Fairbanks Morse Defense

Showing 1–12 of 100 results

The NSC Class ships also prominently display FEC helicopter hangar doors on the flight deck. These heavy duty helicopter hangar door systems are an all-aluminium construction rated to sustain a 40 psf wind loading.

Brand: Hunt Valve Descaling systems that use an accumulator require an accumulator safety shut-off valve to prevent the inadvertent loss of the pneumatic charge into the system due to a low-level condition. Loss of the pneumatic charge typically results in costly unplanned downtime to recharge the system. Hunt Valve’s ceramic seated poppet and plunger-style descale valves are well-suited for use as accumulator low-level safety shut-off valves. Both valve configurations offer the same reliability and long service life as they do on spray header control applications. The following actuation and control options are available for our ceramic seated poppet and plunger-style descale valves: Valve actuation - Electromechanical for maintenance-free operation on our ceramic seated poppet valve - Pneumatic or hydraulic actuation on our plunger-style valves Valve control - Performed via a signal from an accumulator-level control probe (also available from Hunt Valve) Hunt Valve’s accumulator low-level control valve designs are configured to fail closed in all models to prevent the release of the accumulator air charge into the descale system due to a low-level condition.

Developed in collaboration with MagneMotion, Newport News Shipbuilding, and NAVSEA, the Advanced Weapons Elevator (AWE) was originally conceived during the design of the Ford-class aircraft carriers (CVN 78).

The AWE improves the strike-up and strike-down rate of weapons movement from magazines to the flight deck. It employs a ropeless design powered by linear synchronous motors (LSM), advanced control systems, and wireless technology.

The design underwent rigorous qualification trials—including shock, vibration, EMI, load, and reliability testing—and successfully achieved a 24,000 lb load rating and a 150 ft/min speed, exceeding legacy system performance by more than 200% in capacity and 150% in speed.

FEC has been a key contributor to the Office of Naval Research (ONR) consortium focused on automating cargo transfer and stowage to reduce manpower and improve material flow.

The prototype system, known as High Rate Vertical to Horizontal Material Movement (HRVHMM):

-

Integrates linear motors for both vertical and horizontal propulsion of aluminum payload carriers rated up to 6,000 lbs.

-

Features automated loading/unloading and a split elevator platform to resolve replenishment bottlenecks.

-

Can function as a conventional elevator when required.

The HRVHMM was installed and successfully sea-trialed aboard the USNS Washington Chambers (T-AKE 11).

-

Fairbanks Morse Defense and Ward Leonard Automatic Bus Transfers (ABTs) ensure uninterrupted power supply to critical systems by automatically or manually transferring three-phase AC loads during low- or no-voltage events. Trusted for their reliability, ABTs provide seamless switching to keep emergency power sources online when needed most.

Features:

-

Configurable in A1, A2, or A3 architectures

-

Modular design for flexible integration

-

Built and tested to MIL-PRF-17773 specification

-

Trusted reliability in mission-critical applications

Recommended Uses:

-

Emergency power systems on maritime vessels

-

Defence and naval power distribution

-

Mission-critical industrial applications

-

Facilities requiring uninterrupted AC load transfer

-

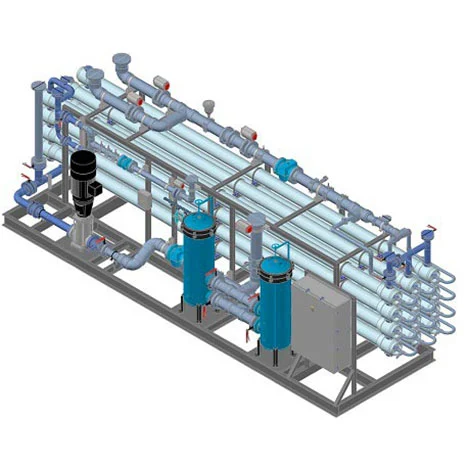

Our two lines of Brackish Water Reverse Osmosis systems have water production capacities ranging from 150 GPD up to 432,000 GPD. Custom units are available upon request.

Capstans are used aboard ships for mooring and warping operations. They consist of a vertically mounted capstan head, available in various diameters, rotated electromechanically or hydraulically to apply force on mooring ropes or cables.

FEC has supplied capstans to numerous U.S. Navy and Coast Guard vessels and recently added Virginia-class submarine (VCS) capstans to its product line.

Brand: Hunt Valve Hunt Valve’s Combo Directional Control Valves are manufactured with the high-quality design features required for the severe duty cycles of steel mill hydraulic systems. The combo valve evolved from Hunt Valve’s H Series Valve product line and has proven to be one of the most reliable valves in the world for low-viscosity fluid applications. This valve line includes the auxiliary control valve products required to complete the functional requirements of a hydraulic control system. These valves are also utilized within oil systems for severe-duty applications where other valves cannot deliver reliable performance. Product Details Combo Directional Control Valves are designed for 95/5 water/oil service and have also performed reliably in the aluminum industry for low-viscosity based fluid applications. The combo valves are rated for up to 5000 psig and flow rates up to 400 GPM. They are designed with heavy-duty seals for zero leakage and are also available as lapped versions where seals are not acceptable in the circuit. All valves offer four-way operation and two- or three-position configuration. The valves can be supplied with a variety of pilot valves to suit the requirements of your circuit. The hydraulic pilot valve version, direct solenoid version and air pilot version are all available.

Montreal Bronze and Fairbanks Morse Defense provide custom-engineered valve solutions, including new design, testing and reverse engineering, to meet all our nuclear customers’ needs while meeting the rigorous quality, material and environmental constraints that may be present. We provide a broad spectrum of products to meet these needs including ball, globe, relief, diaphragm and gate valves as well as additional options such as actuation, hermetic seals, environmental hardening, etc. Commercial Nuclear Valves

- Nuclear Valves

- Ball Valves

- Check Valves

- Diaphragm Valves

- Globe Valves

- Gate Valves

- Specialty Engineered Valves

- Actuated Valves, including:

- Electric Motor

- Solenoid

- Air

- Hydraulic

- Size: .25" - 10"

- Design Specification: ASTM 16.34, ASME Section III, MSS SP-80, MSS SP-88, MIL-SPEC, CSA N285.1-17, per request

- Process Connection: Flange, Butt Weld, Threaded, Swagelok, Greyloc

- Rating: Up to Class 2500

- Material: Stainless Steel (316L, 304, 347, etc.), CuNi, Titanium, Brass, Bronze, Carbon Steel, other on request

- Quality Certifications: ISO 9001:2000, AQAP Z299.4, MIL-STD-798

- Testing Capabilities: NDT, Leak Testing, Pressure Testing, Custom Test Capabilities

- Engineering Capabilities: Life cycle Analysis, Radiation / Environmental Analysis, Seismic Analysis, Flow Analysis

- Additional Capabilities: Hermetic Seal, Radiation-Resistant, Digital Sensors, IP 68

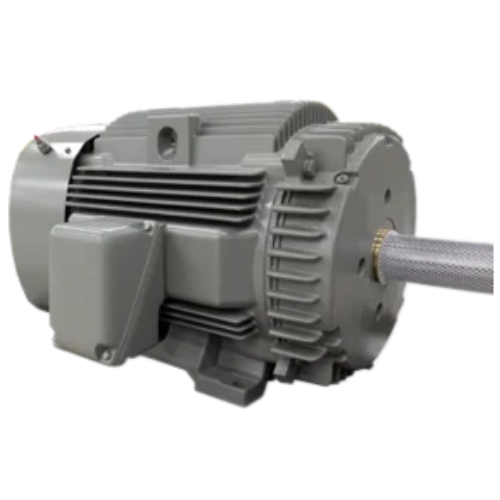

Ward Leonard compressor motors are MIL-Spec built for decades of service in the toughest naval environments. Designed for duty-cycle performance, they provide reliable and efficient power at constant speeds to meet the rigorous demands of naval compressor systems.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Open and closed motor enclosures

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne vibration performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-