Products

Showing 193–204 of 204 results

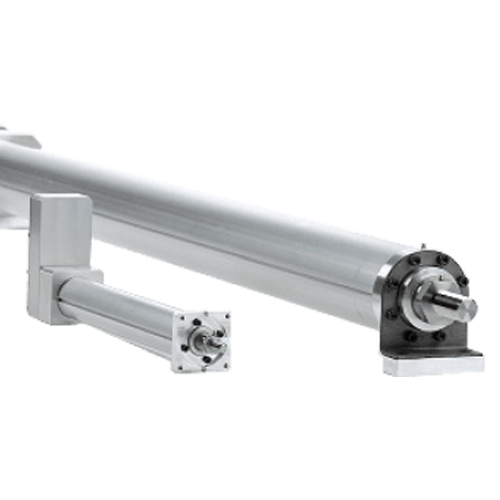

Victory A-Series actuators are built for performance and versatility, offering a clean, efficient, and precise alternative to hydraulic and pneumatic systems. With flexible screw configurations, heavy-duty design, and Hunt’s engineering expertise, these actuators deliver superior thrust, speed control, and programmability—even in harsh or contaminated environments.

Features:

-

Configurable with ball screws, roller screws, or ACME screws for unique load, speed, and duty cycle requirements

-

Internal anti-rotation rod design prevents load/tooling rotation

-

Long ram guide bearing for smooth extension and retraction

-

Wiper and seal system protects against liquid and particle ingress

-

Chrome-plated or stainless steel inner ram for corrosion resistance

-

Screw support bushing reduces vibration, improves dynamic performance, and minimises noise

-

High-capacity angular contact bearings for long life and high thrust capacity

-

Bumpers to safeguard internal components from minor over-travel

-

Multiple mounting options for pivoting or rigid applications

-

Parallel motor mounting option reduces length and allows rear clevis mounting

-

Central rod-end lube port simplifies maintenance

-

Aluminium exterior construction reduces weight and cost

-

Adjustable position sensors with dual T-slots for flexible placement

-

Flexible motor adaptation for most motor types

-

Stroke lengths up to 1,524 mm (60 in.) in 1 mm increments

-

Capable thrust loads up to 11,865 lbf

-

Available in food-grade and full stainless steel designs

Recommended Uses:

-

Military and defence equipment

-

Manufacturing and automation systems

-

Heavy-duty tooling operations

-

Food-grade processing equipment

-

Harsh or contaminated environments

-

Applications requiring high thrust and precise control

-

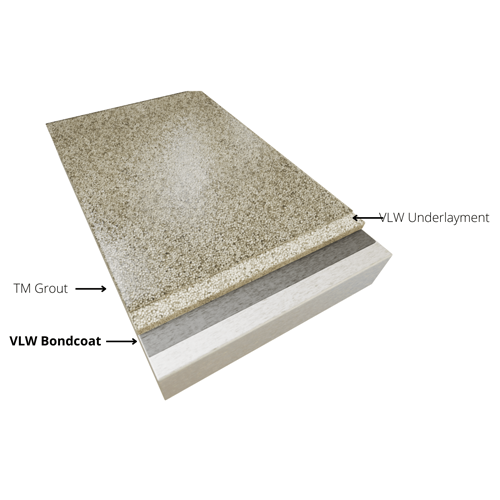

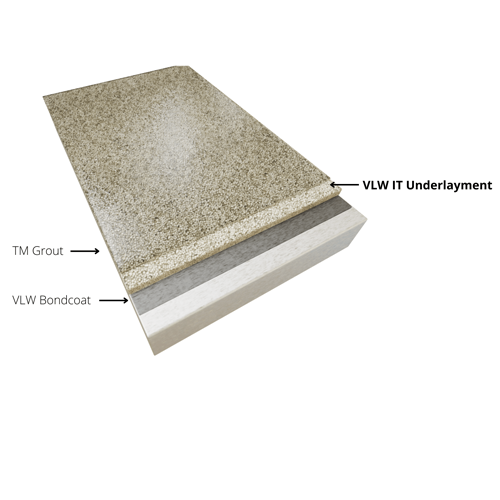

VLW Bondcoat is a high solid, modified epoxy binder resin used as an auxiliary coating for priming substrates for the addition of VLW Underlayment. VLW Bondcoat offers substantial protection against corrosion of metal decking and is not a stand-alone product, it is designed specifically for use with VLW Underlayment.

Very Lightweight Underlayment – IT (VLW-IT) is a 100% solids epoxy resin base mixed with a very lightweight aggregate to form a trowel applied decking underlayment for general use under all deck covering materials. This new version provides an easier to trowel application. Due to the rapid cure of VLW IT Lightweight Underlayment, it can be installed with minimum downtime. It can be applied directly to clean metal or steel. It offers every advantage for lightweight filler sloping/levelling compound for quick turnover maintenance and/or repair installations. Features:

- Improved Trowel ability

- Lightweight

- Low-moisture absorption

- Fast Curing Time

- Create slope for drainage

- Level metal substrate

- Fairing weld beads

Void & Rudder Float Coat is a rust inhibitor formulated to protect tanks and other void spaces on marine vessels. S2S is a self-healing lubricant that penetrates cracks and de-scales rust. Features:

- Rust prevention

- No sandblasting

- No curing time, No downtime

- Environmentally friendly

- Ultra low VOCs

- Eliminates the need to work in confined spaces

- Can be applied to damp, painted and rusted surfaces

- Self-healing lubricant

- Deep rust inhibitor, penetrates rust and descales

- Electrically non-conductive; stops electrolysis

- Rudders

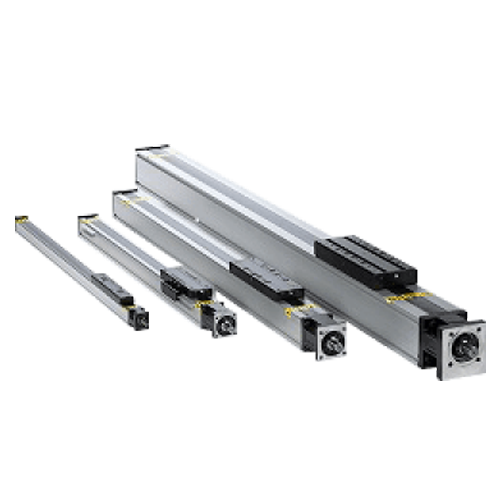

WH (SPEEDLine) Linear Units

The WH (SPEEDLine) series provides high-performance linear motion solutions for single-axis applications, with the flexibility to combine into two- and three-dimensional (X-Y-Z) systems. Featuring a lightweight, compact design with high load ratings, these units are especially effective for Z-axis applications requiring speed, precision, and durability.Features:

-

Maximum speed up to 10 m/s (33 ft/s)

-

Acceleration up to 40 m/s² (131 ft/s²)

-

Repeatability of ±0.05 mm (0.002 in.) under high feed forces

-

Maximum feed force of 5,000 N (1,124 lbf)

-

Payload capacity up to 9,300 N (2,090 lbf)

-

Moment load capacity up to 930 Nm (209 lbf) on carriage

-

Steel-reinforced belt drive for strength and reliability

-

Rubber wipers protect the linear guide from debris

-

Centralised lubrication system for reduced maintenance

-

Lightweight, space-saving construction

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed automation systems

-

Multi-axis (X-Y-Z) motion applications

-

Pick-and-place and handling systems

-

Precision Z-axis operations

-

Industrial assembly and packaging equipment

-

Ward Leonard AC MIL-Spec induction motors have powered U.S. Navy carrier and vessel winches for decades. Their high starting torque and variable speeds make them ideal for gypsy, span wire, saddle winches, and capstans.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Open and closed motor enclosures

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne vibration performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-

Similar in function to capstans, winches incorporate a rotating drum that also allows rope or cable stowage. FEC furnishes a variety of Navy-standard winches in accordance with build-to-print NAVSEA drawings, including:

-

Gypsy winches

-

Saddle winches

-

Spanwire winches

-

Barricade winches

-

Stern dock winches

-

Wipe-Itts Workshop Wipes are heavy-duty textured wipes that effectively remove grease and grime. Features:

- Plastic free – Did you know? More than 30 times the amount of plastic is thrown away in wipes every year than with plastic straws

- Heavy duty cleaning power designed for workshops

- Compostable

- Does not contain petroleum solvents

- Easily remove stubborn stains, odours, ingrained dirt, grease, grime, oil, Stubborn paints, inks and solvents from surfaces in your workshop and on your hands.

Wire Rope Corrosion Control is formulated to protect all types of wire ripe from rust and corrosion. It bonds to metal, displacing water and oxygen and preventing rust long term. Features:

- Rust prevention

- Superior lubricant and penetrant

- Easy to apply

- Long lasting adhesion

- Non-tacky film

- No curing time, No downtime

- Reduces friction and wear

- Electrically non-conductive; stops electrolysis

- Can withstand extreme temperatures

- Non-hazardous and non-toxic

- Can be top-coated with S2S HD Corrosion Shield for extra protection

- Excellent for loosening seized studs and nuts in valves, flanges etc.

- Cranes

- Winches

- Hoists

- Mooring lines

- Towing wire ropes

- Drilling rigs

- Suspension bridges

- Guy wires

- Wire rope slings

- Post tension cables

The WM (POWERLine)—formerly Wiesel POWERLine—features an advanced internal guide system with circulating ball bearings on hardened steel rails. Paired with a precision drive screw, it delivers a balanced solution of power, speed, and accuracy for demanding linear motion applications.

Features:

-

Maximum speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability up to ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Payload capacity up to 6,000 N (1,348 lbf)

-

Moment load capacity up to 600 Nm (134 lbf) on carriage

-

Compact guide and carriage configuration (-370 option)

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports reduce whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

High-precision automation systems

-

Industrial assembly and handling applications

-

Multi-axis linear motion solutions

-

Packaging and processing equipment

-

Long-stroke, high-speed linear drive systems

-

The WM (POWERLine) ZRT—formerly known as Wiesel POWERLine—combines the high travel speeds of a toothed belt drive with the robust, fully integrated ball bearing guide of the POWERLine® series. The -370 models feature a shorter guide system and compact power bridge, delivering powerful performance at a more economical price point.

Features:

-

High-speed toothed belt drive with steel reinforcement

-

Integrated ball-bearing guide system for higher moment load handling

-

Patented self-adjusting sealing cover strip protects against material intrusion

-

Compact -370 option for cost-effective performance

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed linear motion applications

-

Multi-axis automation systems

-

Packaging and assembly equipment

-

Industrial handling systems

-

Environments with potential debris exposure

-

The WV (DYNALine) series—an optimised version of the POWERLine screw-driven rodless actuators—delivers superior moment load capabilities for demanding applications. By coupling primary drive elements with external linear guides, the DYNALine ensures stability and precision, even at high speeds and long stroke lengths.

Features:

-

Maximum travel speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability of ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Dual pre-tensioned ball nuts for higher rigidity and accuracy

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports prevent whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

Applications requiring extremely high moment load capacity

-

Long-stroke, high-speed linear motion systems

-

Heavy-duty industrial automation

-

Precision assembly and material handling equipment

-

Multi-axis systems with demanding load requirements

-