Fairbanks Morse Defense

Showing 85–96 of 101 results

As part of Navy-standard Underway Replenishment (UNREP) systems, FEC manufactures Sliding Padeyes (SPEs) and Kingposts in compliance with NAVSEA build-to-print (BTP) drawings.

FEC also produces BTP-related products to support UNREP operations, such as:

-

Snatch blocks

-

Special fittings

-

Rigging equipment

-

Brand: Hunt Valve For decades, Hunt Valve has supplied critical-duty specialty cylinders for the steel, aluminum, hydro power and mining industries. Applications include aluminum caster cylinders, aluminum furnace tilt cylinders, hydro dam and gate cylinders and nuclear fuel handling system cylinders. Today, we specialize in unique custom design applications where reliability, a long-term service life, a detailed quality assurance program and comprehensive documentation are important. Wicket Gate Servomotors Hunt Valve’s wicket gate servomotors are custom designed and manufactured to meet the strict quality and reliability requirements of hydro energy applications. These robust designs offer special features such as adjustable stroke limiters, hydraulic locking devices, pivoting piston rods and linear transducers for position feedback.

FEC’s weapons design team worked with Lockheed Martin to develop the storage and handling system for the SeaFox Unmanned Underwater Vehicle (UUV), deployed aboard Avenger-class mine countermeasure vessels (MCMs).

-

Rack assembly: Shock-qualified (MIL-S-901), marinized, and fitted with shock isolation mounts for survivability in severe sea states and shock events.

-

Hoist assembly: Pneumatically powered, with separate motors for vertical lift and horizontal traverse.

-

Each shipset includes two hoists and three custom racks, supporting safe storage and launch preparation of SeaFox UUVs.

-

Switchboxes provide a voice-powered telephone system housed in a Grade A shock- and vibration-qualified enclosure. Designed for naval and defence environments, they combine watertight integrity with non-magnetic construction for reliable communication under the toughest conditions.

Features:

-

Shock tested to MIL-S-901

-

Vibration tested to MIL-STD-167

-

Watertight per MIL-STD-108E

-

Dielectric tested for safety

-

Insulation resistance and electrical continuity verified

-

Non-magnetic design (less than 2.0 µ)

-

FEC furnished all fourteen shipsets of the T-AKE hangar door assemblies. These doors consisted of flight deck/cargo doors with stainless steel roller curtains as well as helicopter hangar door assemblies rated at 60 psf. FEC also produced the A-60 rated “Fire Doors” for the T-AKE class ships. The fire doors are electromechanically operated solid panels and are utilized to separate the helicopter hangar area from the interior cargo handling spaces. The doors are fabricated using steel plate with A-60 fire rated insulation applied between the vertical and horizontal door stiffeners. An expandable “fire seal” is present around the perimeter of each door to provide a seal with the adjoining bulkhead to prevent the passing of heat and smoke in the event of fire. These doors have been fully tested and certified to meet the A-60 fire door rating requirements.

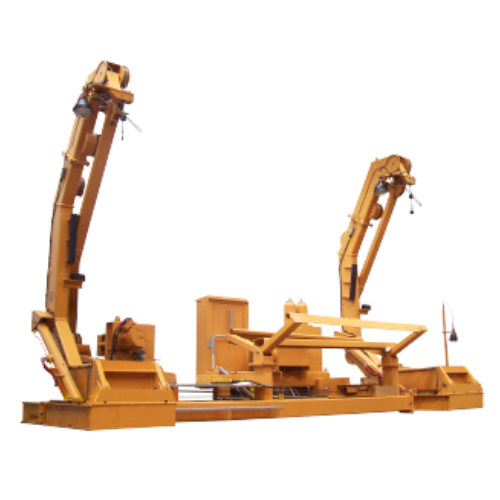

The TWPIV 5.0 A dual-point davit is a modular, self-contained system designed to minimise installation impact while delivering full small-boat operational capability.

-

Safe working load of 5,000 kg (11,023 lbs)

-

All-electric main winch

-

Integrated hydraulic power pack with accumulators for davit luffing

-

Configurable to operate from the vessel’s central hydraulic system

-

SOLAS compliant

-

The TWPIV 5.0 B dual-point davit is a self-contained, palletized system with a safe working load of 5,000 kg (11,023 lbs). It features all-electric independent self-levelling constant tensioning and an all-electric main winch. An integrated hydraulic power pack with accumulators and cylinders provides luffing, making the davit fully SOLAS approved.

This davit incorporates several performance-enhancing features, including:

-

Independent falls tensioning

-

Integrated boat stowage

-

Night operations floodlighting

-

Expandable hook centres

-

Safe working load of 5,000 kg (11,023 lbs)

The TWPIV 5.0 B is SOLAS compliant and serves as the primary davit of the United States Coast Guard.

-

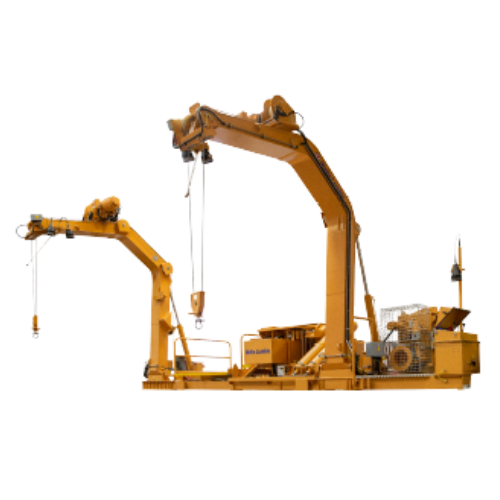

The Welin Lambie type UDTD 3.2 E is an all electric overhead trackway davit interface with the standard Navy 7 M RHIB. Designed and developed for the installation in a hull pocket, the UDTD provides all electric operation. The davit provides variable speed operation for both hoist / lower and traversing in/out board, falls tensioning is also provided. The davit is also equipped for manual operation. The davit is supplied with EMI certification to MIL-STD- 461 E and electrical certification to MIL- STD- 1399.

The VARIOLine actuator is a fully integrated linear drive system built on a robust aluminium profile with ball screw drives and an internal ball bearing guidance system. Designed for smooth force transfer and high precision, it provides an economical and reliable solution for a wide range of linear motion applications.

Features:

-

Extruded aluminium frame design for strength and durability

-

Two frame sizes to suit different applications

-

Thrust capacity up to 787 lbf

-

Travel speeds up to 1.5 m/sec (59 in/sec)

-

Acceleration up to 65.6 ft/sec²

-

Positional repeatability of ±0.001 in.

-

Ideal for Z-axis pick-and-place applications

-

Customisable stroke lengths and motor adaptations

-

Made in the U.S.

Recommended Uses:

-

Pick-and-place automation (Z-axis)

-

Industrial assembly systems

-

Manufacturing and material handling equipment

-

Precision positioning applications

-

General linear motion requirements

-

Victory A-Series Food Grade Actuators are engineered for performance in demanding environments such as food production, packaging, and pharmaceutical manufacturing. With robust materials, ingress protection, and food-safe components, they provide precise, reliable motion control while meeting industry hygiene standards.

Features (FG1 Option):

-

Anodized aluminium body with food-grade epoxy coating

-

300 series stainless steel inner ram and rod-ends

-

IP67 ingress protection against liquids and particulates

-

Food-grade rod wipers and seals

-

Infinitely adjustable proximity limit sensors

-

Predictable motion with reliable L10 life and maintenance intervals

-

Available across the full Victory A-Series line

-

Made in the U.S.

Features (FG2 Option):

-

Full 300 series stainless steel exterior construction

-

IP67 ingress protection against liquids and particulates

-

Food-grade rod wipers and seals

-

Infinitely adjustable proximity limit sensors

-

Suitable for caustic and washdown environments

-

Predictable motion with reliable L10 life and maintenance intervals

-

Available across the full Victory A-Series line

-

Made in the U.S.

Recommended Uses:

-

Food production equipment

-

Food packaging systems

-

Pharmaceutical manufacturing

-

Hygienic processing environments

-

Applications requiring corrosion resistance and washdown protection

-

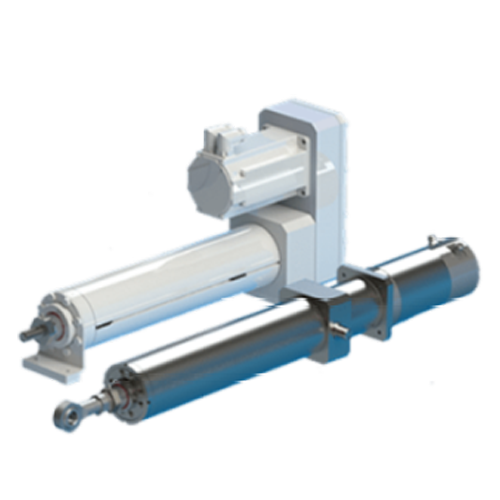

Victory A-Series actuators are built for performance and versatility, offering a clean, efficient, and precise alternative to hydraulic and pneumatic systems. With flexible screw configurations, heavy-duty design, and Hunt’s engineering expertise, these actuators deliver superior thrust, speed control, and programmability—even in harsh or contaminated environments.

Features:

-

Configurable with ball screws, roller screws, or ACME screws for unique load, speed, and duty cycle requirements

-

Internal anti-rotation rod design prevents load/tooling rotation

-

Long ram guide bearing for smooth extension and retraction

-

Wiper and seal system protects against liquid and particle ingress

-

Chrome-plated or stainless steel inner ram for corrosion resistance

-

Screw support bushing reduces vibration, improves dynamic performance, and minimises noise

-

High-capacity angular contact bearings for long life and high thrust capacity

-

Bumpers to safeguard internal components from minor over-travel

-

Multiple mounting options for pivoting or rigid applications

-

Parallel motor mounting option reduces length and allows rear clevis mounting

-

Central rod-end lube port simplifies maintenance

-

Aluminium exterior construction reduces weight and cost

-

Adjustable position sensors with dual T-slots for flexible placement

-

Flexible motor adaptation for most motor types

-

Stroke lengths up to 1,524 mm (60 in.) in 1 mm increments

-

Capable thrust loads up to 11,865 lbf

-

Available in food-grade and full stainless steel designs

Recommended Uses:

-

Military and defence equipment

-

Manufacturing and automation systems

-

Heavy-duty tooling operations

-

Food-grade processing equipment

-

Harsh or contaminated environments

-

Applications requiring high thrust and precise control

-

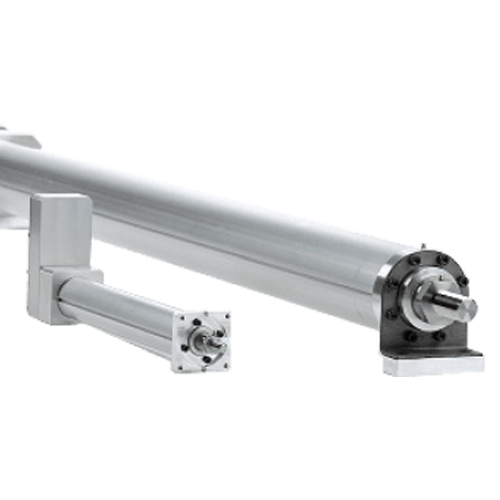

WH (SPEEDLine) Linear Units

The WH (SPEEDLine) series provides high-performance linear motion solutions for single-axis applications, with the flexibility to combine into two- and three-dimensional (X-Y-Z) systems. Featuring a lightweight, compact design with high load ratings, these units are especially effective for Z-axis applications requiring speed, precision, and durability.Features:

-

Maximum speed up to 10 m/s (33 ft/s)

-

Acceleration up to 40 m/s² (131 ft/s²)

-

Repeatability of ±0.05 mm (0.002 in.) under high feed forces

-

Maximum feed force of 5,000 N (1,124 lbf)

-

Payload capacity up to 9,300 N (2,090 lbf)

-

Moment load capacity up to 930 Nm (209 lbf) on carriage

-

Steel-reinforced belt drive for strength and reliability

-

Rubber wipers protect the linear guide from debris

-

Centralised lubrication system for reduced maintenance

-

Lightweight, space-saving construction

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed automation systems

-

Multi-axis (X-Y-Z) motion applications

-

Pick-and-place and handling systems

-

Precision Z-axis operations

-

Industrial assembly and packaging equipment

-