Specialised Weapons & Material Handling

Showing 1–12 of 17 results

The NSC Class ships also prominently display FEC helicopter hangar doors on the flight deck. These heavy duty helicopter hangar door systems are an all-aluminium construction rated to sustain a 40 psf wind loading.

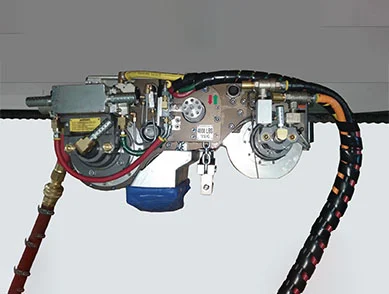

Developed in collaboration with MagneMotion, Newport News Shipbuilding, and NAVSEA, the Advanced Weapons Elevator (AWE) was originally conceived during the design of the Ford-class aircraft carriers (CVN 78).

The AWE improves the strike-up and strike-down rate of weapons movement from magazines to the flight deck. It employs a ropeless design powered by linear synchronous motors (LSM), advanced control systems, and wireless technology.

The design underwent rigorous qualification trials—including shock, vibration, EMI, load, and reliability testing—and successfully achieved a 24,000 lb load rating and a 150 ft/min speed, exceeding legacy system performance by more than 200% in capacity and 150% in speed.

FEC has been a key contributor to the Office of Naval Research (ONR) consortium focused on automating cargo transfer and stowage to reduce manpower and improve material flow.

The prototype system, known as High Rate Vertical to Horizontal Material Movement (HRVHMM):

-

Integrates linear motors for both vertical and horizontal propulsion of aluminum payload carriers rated up to 6,000 lbs.

-

Features automated loading/unloading and a split elevator platform to resolve replenishment bottlenecks.

-

Can function as a conventional elevator when required.

The HRVHMM was installed and successfully sea-trialed aboard the USNS Washington Chambers (T-AKE 11).

-

Capstans are used aboard ships for mooring and warping operations. They consist of a vertically mounted capstan head, available in various diameters, rotated electromechanically or hydraulically to apply force on mooring ropes or cables.

FEC has supplied capstans to numerous U.S. Navy and Coast Guard vessels and recently added Virginia-class submarine (VCS) capstans to its product line.

Motor controllers, operator stations, power panels, disconnect switches/panels, and junctions boxes can all be furnished by FEC in accordance with the previously mentioned electrical specifications. FEC has significant experience with electrical enclosures of all kinds and can perform the electrical design, assembly and testing required to ensure our deck machinery meets the fit, form and function desired for Navy shipboard use.

For decades, FEC has been the trusted supplier of complex cargo-handling systems, along with elevator and conveyor field service and spare parts for the Navy, Coast Guard, and shipbuilders.

Applications include handling palletised cargo such as missiles, bombs, and general stores. FEC is the primary supplier of the Advanced Weapons Elevator (AWE) for the Ford-class aircraft carriers and continues to support new lift systems, including the ammunition lift system for the DDG class destroyers.

FEC is the leading provider of shipboard dumbwaiters for the US Navy. Available in a range of sizes, capacities, and travel lengths, these systems are installed across multiple ship classes to facilitate efficient vertical transport of small loads.

As a full-service elevator supplier, FEC provides a comprehensive line of elevator safety equipment to support Navy and Coast Guard operations.

The fork truck guard, an FEC signature product for more than 20 years, prevents forklift trucks from striking elevator trunks. These assemblies are installed flush with the deck and extend or retract as needed. FEC supplies both complete guard assemblies and replacement parts.

Federal Equipment Company has emerged as a leader in supplying, repairing and installing vertical rolling doors for both the United States Coast Guard and Navy. Federal Equipment Company supplies all repair parts for the helicopter hangar doors either directly from the OEM or manufactured in-house to exceed OEM requirements.

FMD is the Navy’s trusted choice for specialised hoists supporting weapons and cargo handling on aircraft carriers and amphibious ships.

-

Low headroom trolley-type pneumatic hoists developed by FEC resolved a fleet-wide obsolescence issue and are widely used for weapons assembly and transfer.

-

Hoists undergo extreme qualification testing, including shock and vibration.

-

Options include manual chain hoists, electric hoists, wire rope or chain types, available in a range of capacities and lifts.

-

Accessories such as pendant controls, monorails, turntables, and track clamps are also available.

-

All hoist systems are tested and certified in accordance with applicable naval specifications.

-

One of the more notable features on FEC’s Advanced Weapons Elevator (AWE) system is the first fully qualified Human Machine Interface (HMI) Operator Stations. These unique panels are the first touchscreens implemented on an aircraft carrier that have successfully undergone all the exhaustive tests to meet EMI, shock, and vibration requirements necessary for use in a shipboard weapons systems. The HMI provides a user friendly multi-screen interface while allowing more panels and data to be displayed at multiple deck locations simultaneously in a much more compact space relative to traditional panels. The software based HMI application also permits added flexibility, troubleshooting and maintenance capabilities. Adaptable for use in other material and weapons handling systems, the HMI operator stations increase ship’s force control and communication as well as system monitoring and diagnostics to maximize operational functionality and readiness.

FEC designed and manufactured the helicopter hangar doors for the LCS Independence variant. These doors are also manufactured from aluminum and rated for 40 psf wind load. These port and starboard roller curtain door assemblies meet all the LCS specification requirements including shock and EMI qualifications.