Products

Showing 145–156 of 204 results

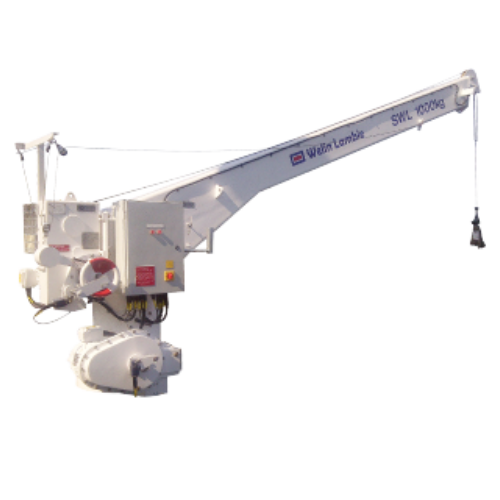

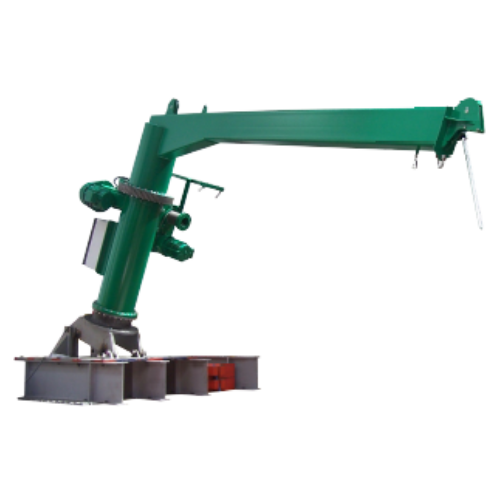

The SARB (E/H) 1.0A and 1.3A models provide both electric and hydraulic operation. Each is supplied with a self-contained power pack and accumulator, offering a safe working load of up to 1,400 kg (3,086 lbs) with a 70° slew angle.

The standard winch configuration is power-hoist with gravity lowering, with power-hoist/power-lower available as an option.

The SARBE 8A davit is a self-contained, all-electric slewing davit with a safe working load of up to 1,600 kg. It is designed for low installation impact and features electric hoisting with gravity lowering, as well as power-hoist and power-lower options. Slewing is achieved via electric motor and/or manual operation.

The SARBE 8A can be supplied with a fixed slewing radius of 3.2 to 5.6 m. Height adjustments can be made to suit restricted installation conditions.

For weight-sensitive applications such as fast ferries, the SARBE F version is available in marine-grade aluminium and stainless steel for enhanced durability.

The SARBE 8C variant allows both the vertical post and winch to remain stationary while the arm rotates, providing 360° slewing operation.

This unique design is ideal for restricted installation envelopes, enabling the davit to be placed against the vessel structure or at the deck edge with a “zero” tail radius.

The SARBE 8C is a self-contained, all-electric slewing davit with a safe working load of up to 1,400 kg (3,086 lbs).

The SASD davits are designed for shore-based operations such as inshore rescue boat stations and training facilities. They feature both powered hoisting/lowering and full manual operation, with falls tensioning for all-weather use.

Often installed in remote locations and operated in adverse weather, these davits are designed with simplicity and minimal maintenance in mind, ensuring ease of use for rescue volunteers. Standard features include davit head and area lighting, as well as vandal-proof guards.

Ward Leonard MIL-Spec servo motors support fan applications ranging from aerofoil and mixed-flow to centrifugal and CPS types. Built to naval standards, they ensure durability and efficiency across decades of sea service.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Open and closed motor enclosures

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne vibration performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-

Plaztuff Hyspec Polymer sheet is a modified High Molecular Weight Polyethylene (HMWPE) made to our exact specification for the purposes of manufacturing a wide range of engineering products using extrusion welding and sheet fabrication techniques. Polyethylene’s are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance, and a wide range of properties. Polyethylenes provide good resistance to organic solvents, degreasing agents and electrolytic attack. They have higher impact strength, but lower working temperatures than Polypropylene. They are light in weight, resistant to staining and have very low moisture absorption rates. Polyethylenes are easy to distinguish from other plastics as they float in water. Plaztuff HMWPE is lightweight (1/8 the weight of mild steel), high in tensile strength and is as simple to machine as wood and with extrusion welding equipment is fully weldable. Plaztuff is self-lubricating, offers excellent impact resistant, long wearing, has moderate abrasion resistant and is corrosion resistant. Plaztuff sheet is built to a high specification with a very high UV factor and performs well in all environments with good weathering properties and a 20+ UV life. Plaztuff is also non-toxic and non-staining and meets FDA and USDA certification acceptance for food and pharmaceutical equipment and is a good performer in applications up to 82°c. Use Cases:

- Sheets and Welding

- Construction

- Panels

- Displays

- Marine

- Pontoons

- Boats

- Jetties

- Tanks

- ISO Tanks

- Tanks General

- Transport

- Trailers

- Liners

- Vehicles

- Bins

- Food Boxes

- Hoppers

- Waste Bins

- Miscellaneous

- Pools

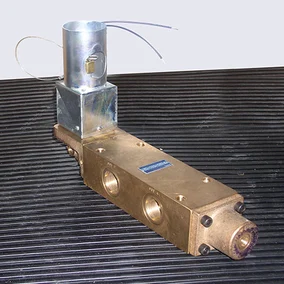

Brand: Hunt Valve Hunt Valve’s Single Plunger Series Valves are low-pressure air and water valves. Therefore, this valve offers superior performance when functioning within air circuits contaminated by water moisture without having any negative effect on the valve. The brass bodies and the stainless steel plungers have made this valve one of the most reliable air products for severe service in the industry. Product Details The single plunger valve is designed with a brass casting or bar stock housing and a stainless steel plunger. The easily replaceable air pilot simplifies the shifting action of the valve, but with a high force for positive shifting. The single plungers are rated for up to 250 psig and are available in sizes ranging from 3/8 inch to 2 inches. They are available with two-, three-, four- or five-way operation and with two- or three-position configuration. The valves are designed with heavy-duty U-packing seals for zero leakage and are easily replaceable to maintain an airtight system.

As part of Navy-standard Underway Replenishment (UNREP) systems, FEC manufactures Sliding Padeyes (SPEs) and Kingposts in compliance with NAVSEA build-to-print (BTP) drawings.

FEC also produces BTP-related products to support UNREP operations, such as:

-

Snatch blocks

-

Special fittings

-

Rigging equipment

-

Brand: Hunt Valve For decades, Hunt Valve has supplied critical-duty specialty cylinders for the steel, aluminum, hydro power and mining industries. Applications include aluminum caster cylinders, aluminum furnace tilt cylinders, hydro dam and gate cylinders and nuclear fuel handling system cylinders. Today, we specialize in unique custom design applications where reliability, a long-term service life, a detailed quality assurance program and comprehensive documentation are important. Wicket Gate Servomotors Hunt Valve’s wicket gate servomotors are custom designed and manufactured to meet the strict quality and reliability requirements of hydro energy applications. These robust designs offer special features such as adjustable stroke limiters, hydraulic locking devices, pivoting piston rods and linear transducers for position feedback.

FEC’s weapons design team worked with Lockheed Martin to develop the storage and handling system for the SeaFox Unmanned Underwater Vehicle (UUV), deployed aboard Avenger-class mine countermeasure vessels (MCMs).

-

Rack assembly: Shock-qualified (MIL-S-901), marinized, and fitted with shock isolation mounts for survivability in severe sea states and shock events.

-

Hoist assembly: Pneumatically powered, with separate motors for vertical lift and horizontal traverse.

-

Each shipset includes two hoists and three custom racks, supporting safe storage and launch preparation of SeaFox UUVs.

-

Switchboxes provide a voice-powered telephone system housed in a Grade A shock- and vibration-qualified enclosure. Designed for naval and defence environments, they combine watertight integrity with non-magnetic construction for reliable communication under the toughest conditions.

Features:

-

Shock tested to MIL-S-901

-

Vibration tested to MIL-STD-167

-

Watertight per MIL-STD-108E

-

Dielectric tested for safety

-

Insulation resistance and electrical continuity verified

-

Non-magnetic design (less than 2.0 µ)

-

FEC furnished all fourteen shipsets of the T-AKE hangar door assemblies. These doors consisted of flight deck/cargo doors with stainless steel roller curtains as well as helicopter hangar door assemblies rated at 60 psf. FEC also produced the A-60 rated “Fire Doors” for the T-AKE class ships. The fire doors are electromechanically operated solid panels and are utilized to separate the helicopter hangar area from the interior cargo handling spaces. The doors are fabricated using steel plate with A-60 fire rated insulation applied between the vertical and horizontal door stiffeners. An expandable “fire seal” is present around the perimeter of each door to provide a seal with the adjoining bulkhead to prevent the passing of heat and smoke in the event of fire. These doors have been fully tested and certified to meet the A-60 fire door rating requirements.