Products

Showing 133–144 of 204 results

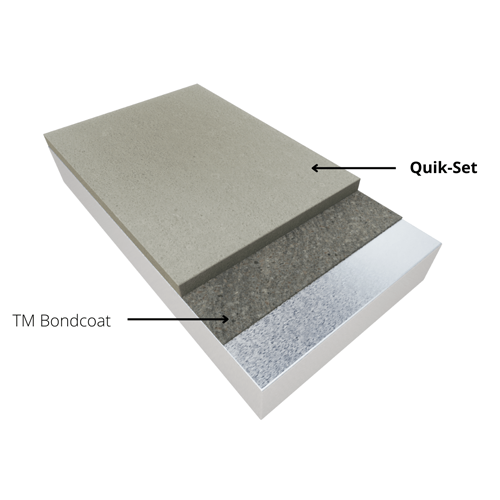

Quik-set is a lightweight underlayment screed used in thin gauge applications for levelling and fairing welds. It is a synthetic resin mastic that, when trowel applied to properly cleaned deck surfaces, will adhere without the use of mechanical fasteners. It has good troweling characteristics and is normally applied in feather edge thicknesses. Quik-Set is approved as an IMO primary deck covering material with low flame spread characteristics and does not produce excessive quantities of smoke and toxic products from combustion. It is moisture resistant, has high indentation resistance and is fast setting. Features:

- Lightweight

- Fast setting

- Good adhesion

- Resilient

- Flexible

- Good indentation resistance

- Trowels to a smooth finish

- Coast Guard Wheel-mark approved

- Mil-Spec QPL material

- All steel, ferrous metal or aluminium surfaces that require levelling or fairing welds

Remote push button stations are engineered for shipboard control applications that demand heavy-duty, watertight master switches. Built to MIL-DTL-2212 standards, these stations withstand high shock, vibration, and abuse, ensuring decades of reliable performance. Configurable with up to seven elements, they can include maintained or momentary contacts, as well as indicating lights, to suit specific operational needs.

Features:

-

Supports 1–7 remote functions per device

-

Available with dimmable light covers and tamper-proof covers

-

LED bulb options for efficiency and longevity

-

Custom design to meet application requirements

-

Compliant with MIL-DTL-2212 standards

-

Fairbanks Morse Defense and Maxim manufacture resilient mount snubbers to Navy Standard Drawing 112-1889944 for use in conjunction with equipment being furnished by Maxim for DDG 51 Flight III. Maxim has developed the capabilities to manufacture resilient mount snubbers, for machinery mounts, to the following Navy Standard Drawings:

- 112-1889946

- 112-1889949

- 112-1889943

- 112-1889942

- 112-1889944

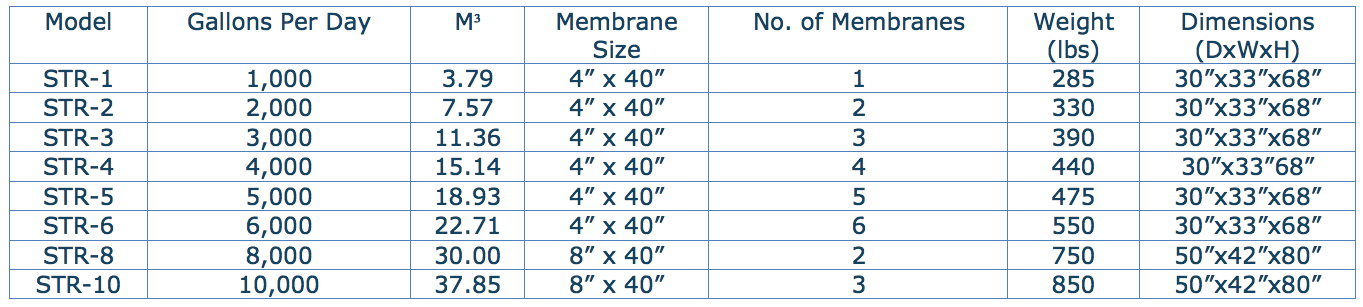

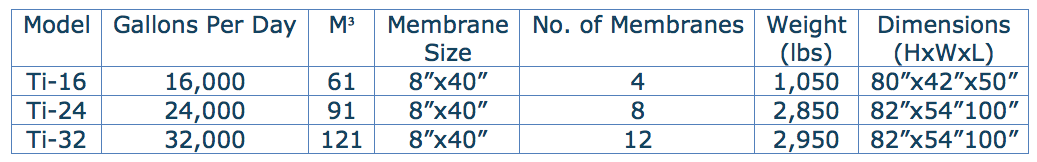

The Titanium Series Reverse Osmosis Systems have fresh water production capacities ranging from 16,000 GPD to 32,000 GPD. Custom units are available upon request.

Fairbanks Morse Defense and Ward Leonard MDR Rotary Relays deliver higher contact ratings than comparable relays used in military and heavy-industrial applications. By eliminating the need to connect contacts in series, the MDR design simplifies wiring and frees terminals for additional circuitry. Engineered to MIL-R-19523B (SH) standards and QPL tested for vibration, shock, and endurance, these relays provide unmatched reliability and performance, with over 500,000 proven operations.

Features:

-

Contact arrangements from 4PDT to 12PDT

-

Increased contact ratings without the need for series connections

-

Standard and low-noise models available

-

Backwards compatible with relays from other manufacturers

-

High-reliability design for mission-critical environments

Recommended Uses:

-

Naval and defence electrical systems

-

Heavy-industrial control applications

-

High-current, high-reliability switching needs

-

Environments requiring vibration- and shock-tested components

-

Brand: Hunt Valve At Hunt Valve, our innovative engineering solutions include specialty hydraulic products such as rotary joints. A rotary joint is usually a one-off design that is specific to the individual customer application. This product can be as simple as a single pass unit or as complex as a multi-stage unit with up to 22 passes. The rotary joint is a critical piece of equipment in the steel-making process. They are located in the hot metal mill at the basic oxygen furnace (BOF), in the continuous caster ladle turret and in the argon oxygen decarburization (AOD) process. Any failure at this end of the mill can lead to costly downtime, creating a major outage throughout the entire mill line. Our innovative engineering team has the expertise to redesign and upgrade an existing rotary joint, transforming it into a more efficient and reliable product.

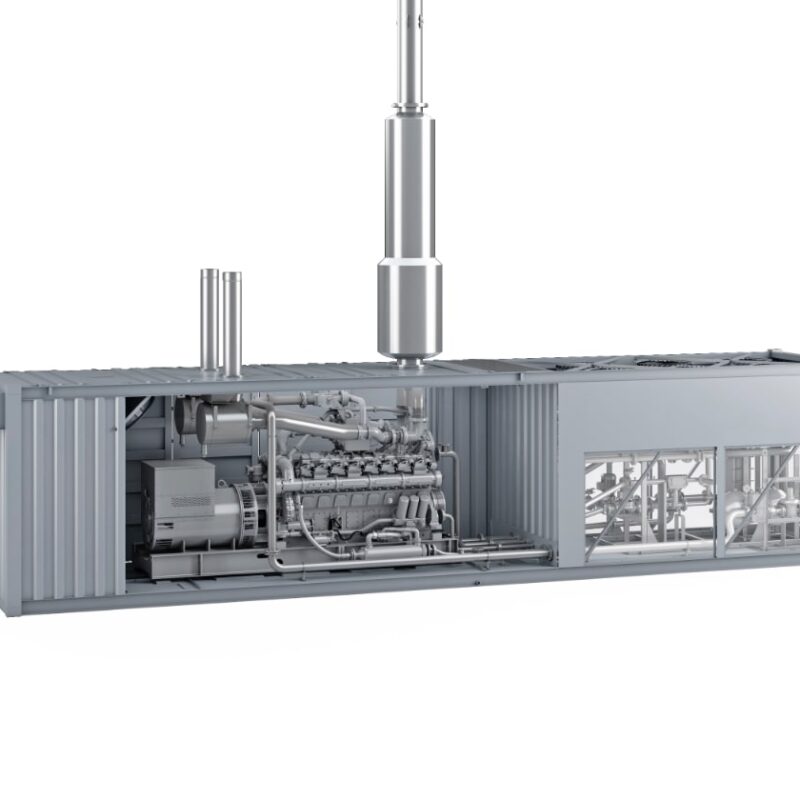

- A robust & reliable solution for maximum versatilityInnovative compact engine design and combustion technology for versatile use from 190 to 1,150 Kw. This Guascor Energy engine series accepts all type of combustion gases from syngas to propane and blending.

SL Engines

Ideal for power generation, cogeneration/trigeneration, mechanical drive and marine applications – the lean burn, electronically carbureted SL gas engines have an output range from 209 to 1150 kWb at 50 Hz and 60 Hz.Providing an excellent solution when fueled by natural gas, landfill and sewage gas, flare and well gas, LPG& propane, syngas and also hydrogen, the SL Series is a cost-efficient choice in both implementation and service. Great fuel flexibility and with fuel blending availability, this series is also an eco-friendly solution. Along with fast start availability, a high load acceptance capability is one of the main features of this engine series. Robust, reliable and with superb fuel flexibility, this Otto cycle turbocharged and charge-aircooled engine series features a single or double circuit cooling system. There is a high temperature option in the main cooling circuit, with temperatures of up to 120ºC possible. If required, the auxiliary cooling circuit can deliver a different temperature. The main cooling circuit may also feature an oil cooler. With a dry or wet exhaust manifold, single or double stage charge-air cooler and reduced oil consumption, this series of engines can include emissions control if required and is compliant with the latest U.S emissions standards, being EPA certified for natural gas power generation, for example. Supplied as a standalone engine, genset or in a fully containerised unit, integrated GCS-E and GCS-G genset control systems are available for some applications.Tri-fuel mobile solution

Three different types of fuel without any power derate due to input fuel: this is what our G-56SL engine offers in this 45 ft containerized unit, in compliance with the strictest emission levels defined by the United States Environmental Protection Agency (EPA). A reliable, flexible and high performing solution, that reduces costs and ensures high operational availabilitySM Engines

Lean burn and electronically carbureted the SM series of gas engines provide an excellent solution for power generation, cogeneration and trigeneration applications. Fueled by natural gas, landfill and sewage gas, LPG& propane, outputs range from 1055 to 1100 kWb when fueled with natural gas, landfill or sewage gas in 50 Hz and 60 Hz configurations. When fueled with propane or LPG, outputs are from 275 to 906 kWb at 50 Hz and 60 Hz, respectively. This Miller cycle series of engines are turbo-charged and include two-stage charge-air cooling if required. A double cooling circuit system allows different temperatures to be achieved in the auxiliary cooling circuit while an oil cooler in an additional option for the main cooling circuit. Among the key characteristics of this series of engines are standard interchangeable parts and very high operational availability – key competitive advantages. With a dry or wet exhaust manifold configuration, an emissions control option means this series is compliant with the latest U.S. emissions standards and it has reduced oil consumption too. This engine series may be supplied as a stand-alone engine, as a genset or as a fully containerised unit.SR Engines

Robust and reliable, the rich burn, electronically carbureted SR Series gas engines offer great performance for power generation and cogeneration applications. Outputs range from 180 to 870 kWb at 60 Hz and this series may be fueled natural gas and well gas with superb fuel flexibility. This ecofriendly engine series meets the latest U.S. emissions standards and has great flexibility for load acceptance too. Turbocharged and with single or double stage charge-air cooling, the SR Series features a double circuit cooling system in which different auxiliary cooling circuit temperatures are achievable. With a wet exhaust manifold, the SR Series machines are supplied as a stand-alone engine, as a genset or as a fully containerised unit. Sailor Paste is a CPC 500 infused corrosion paste engineered for heavy-duty naval and defense corrosion protection. Provides a thick, long-lasting protective barrier. Sailor Putty can be top coated with polysiloxane paint making it suitable for both permanent and temporary corrosion control during vessel maintenance. Apply by brushing, rolling, or spreading. CPC 500 is a U.S. Navy MIL-PRF 16173E MILSPEC approved high-performance, long-lasting rust inhibitor. Tough enough to withstand the Navy’s crushing deployment cycle. Features:

- MIL-PRF 16173E approved corrosion compound

- Thick, long lasting corrosion protection barrier

- Stops electrolysis caused by dissimilar metals

- Self-healing

- No curing time, No downtime

- Easy to use

- Apply by brushing, rolling, or spreading.

- Shipboard metal surfaces

- Structural components and fittings

- Fleet maintenance and preservation works

- Naval repair and maintenance operations

Sailor Putty is an industrial corrosion prevention tape infused with a MIL-PRF 16173E MILSPEC rust inhibitor, purpose-built for shipboard and defence corrosion repair. Unlike traditional petrolatum tapes that require surface preparation and primer paste, S2S Sailor Putty is a simple, one-step application process, reducing maintenance time and complexity during naval operations. Features:

- Use on piping and pipelines, fittings, flanges, valves, pilings and pier structures, splash zones, and structural steel and support bases

- Stops electrolysis caused by dissimilar metals

- One-step application process

- No curing time, No downtime

- Effective on damp, rusted, and painted surfaces

- Suitable for above and below waterline applications

- Shipboard piping and pipelines

- Pilings, pier structures and splash zones

- Structural steel and support bases

Sailor Wipes are durable, disposable wipes infused with CPC 500, a U.S. Navy MIL-PRF 16173E MILSPEC approved corrosion inhibitor developed for shipboard corrosion control and maintenance operations. Designed for demanding naval environments, the wipes clean and polish metal surfaces while leaving behind a dry, protective micro-barrier that resists corrosion and electrolysis caused by dissimilar metals. Engineered to withstand extended deployment cycles, Sailor Wipes provide a practical solution for shipboard corrosion maintenance, touch-up protection, and routine preservation of exposed metal components without curing time or operational downtime. Features:

- Suitable for shipboard and metal surfaces

- MIL-PRF 16173E approved corrosion inhibitor formulation

- Stops electrolysis caused by dissimilar metals

- Easy to use

- No curing time, No downtime

- Dry to the touch protective barrier

- Naval vessels

- Shipboard equipment and fittings

- Electrical housings

- Fleet maintenance and corrosion control