Products

Showing 121–132 of 204 results

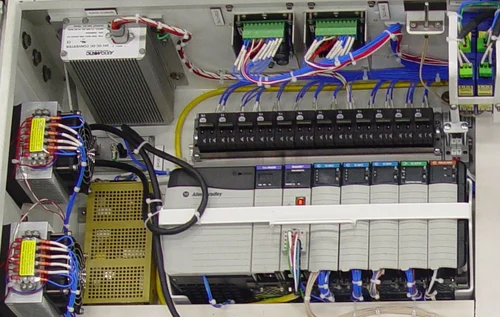

Today many shipboard systems have increased automation requiring digital controls, solid state relays in lieu of electromechanical relays, and invoke PLCs for increased service life, reliability, flexibility, and compatibility with newer technology. FEC has a solid background incorporating PLCs in weapons and material handling systems, particularly in the elevator and conveyor arena.

Brand: Hunt Valve Check valves are required at the pump discharge lines to automatically prevent the backflow of descale water from the active pump units into a standby pump or a pump in the bypass mode. At Hunt Valve, our check valves are built with hardened seats to withstand the frequency of operation without failure. They are manufactured with the high-quality design features required for the severe duty cycles of the steel mill industrial descale system. The poppet design is engineered for reliability and longevity in the dirty descale water environment.

Ward Leonard pump motors are engineered to endure harsh naval environments, reliably powering pumps for brine, graywater, ground food waste, cooling, bilge, firefighting, and more.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Open and closed motor enclosures

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne vibration performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-

Purasolve Brake Cleaner is an ultra-safe, slow-evaporating solvent engineered for brakes and other precision technical applications. Delivering a spotless, residue-free finish, it outlasts conventional brake cleaners by up to 20 times—without the health, safety, or environmental risks posed by toxic or explosive formulations.

Features:

- Advanced safety solvent for brake and technical cleaning

- Residue-free finish for critical applications

- Slow evaporation allows extended cleaning time

- Up to 20× longer-lasting than conventional cleaners

- Free from chlorinated and halogenated solvents

- Safer for workers, equipment, and the environment

Recommended uses:

- Brake maintenance and cleaning in automotive, industrial, and defence sectors

- Technical cleaning where residue-free results are essential

- Workshops seeking a safe, long-lasting alternative to standard brake cleaners

Purasolve EverSafe is a rechargeable aerosol spray system that replaces traditional disposable aerosols with a safer, cost-effective, and environmentally responsible solution. Powered by inert compressed air, EverSafe eliminates harmful propellants, significantly reducing fire and explosion risks while lowering operational costs through the use of bulk chemicals.

The EverSafe system is endlessly reusable, helping to reduce hazardous waste from empty aerosol cans. It is ideal for organisations seeking to streamline chemical dispensing without compromising safety or efficiency.

Features

- Cost-effective alternative to disposable aerosol cans

- Compatible with a wide range of chemicals and solvents

- Uses bulk chemicals to reduce costs and waste

- Powered by inert compressed air — no harmful propellants

- Available in two convenient sizes for different applications

- Easy and quick to refill, minimising downtime

- Environmentally friendly — reduces aerosol can wastage

Recommended Uses

- Industrial workshops and service centres

- Defence and aerospace facilities

- Mining, manufacturing, and heavy industry

- Any facility seeking safer chemical atomisation and reduced waste

Refilling Options

- Manual Refilling: Easily fill and pressurise EverSafe units using any standard workshop air compressor.

- Power-Fill Station: For high-volume operations, the Purasolve Power-Fill Station enables seamless, automatic refills without disassembly, delivering precise chemical and compressed air quantities for consistent performance.

A fully recyclable parts and equipment cleaner formulated from a high-purity hydrocarbon solvent, designed for safe and effective cleaning of metal components. Purasolve Parts Cleaner delivers long-lasting performance and works as a reliable parts washer solvent, especially when paired with Purasolve filters, extending solvent life for up to 18 months. It replaces traditional hazardous cleaners with a non-flammable solvent that supports a safer, low-odour working environment.

Key Benefits:

- Fully recyclable formulation that reduces waste and disposal costs

- Maintains cleaning efficiency for up to 18 months with Purasolve Filters

- Non-flammable, non-explosive, and low odour for improved workplace safety

- Benzene-free with low vapour pressure to minimise health risks

- Reduces PPE requirements and handling hazards

- Suitable as a metal parts cleaner across multiple industries

Typical Applications:

- Degreasing and cleaning automotive, aviation, and industrial components

- Ideal for workshops, maintenance facilities, and heavy equipment service areas

- Effective in soak tanks, ultrasonic cleaners, and manual cleaning processes

- Supports safe replacement of conventional hazardous parts washer solvents

Purasolve Parts Cleaner SK is a fully recyclable, low vapour, benzene free, high purity hydrocarbon degreasing solvent for use in parts washers. It has been specially designed for the easy removal of heavy bearing grease and mining applications. Features:

- High-Tech Parts Washing Solution

- Fully Recyclable

- Lasts for a minimum of 18 months when used with Purasolve Filters

- Developed to Replace Dangerous Solvents for Parts Cleaning

- Non-Flammable and Non-Explosive

- No Bacteria or Enzymes

- Extreme Grease Removing Action

- Improves Worker Health & Safety

- Reduced PPE requirement

- Parts washing systems

- Parts Soaking

- Heavy Bearing Grease

- Metal Cleaning

Purasolve Power-Fill Station enables quick and efficient refilling of Purasolve EverSafe dispensers without the need to disassemble the sprayer. Each refill delivers a standardised amount of chemical along with the required compressed air, ensuring consistent performance and minimising downtime in busy industrial or Defence environments.

Features

- Automatic refill system for Purasolve EverSafe dispensers

- Eliminates disassembly, reducing handling time and effort

- Delivers precise chemical and compressed air with each refill

- Increases efficiency in maintenance and operations

Recommended Uses

- Industrial workshops

- Defence and aerospace maintenance facilities

- Any operation using Purasolve EverSafe Atomisers for controlled chemical application

The Purasolve Parts Washer PS6 is a heavy duty Parts Washer Cleaning System that increases safety and reduces through-life costs through a unique recycling system. Features:

- Versatile recycling solvent cleaning station

- Three methods of cleaning – flexible hose, handheld brush and parts soaking

- Integral recycling micro-filtration extends solvent life

- Utilises fully recyclable safety solvents for ultimate worker safety

- Significant reductions in solvent usage and disposal cost

- Heavy maintenance and MRO applications in transport, mining, defence, construction equipment servicing and other industrial cleaning applications

Purasolve Rotary Parts Washer Detergent is a heavy-duty cleaning powder formulated for optimal performance in Purasolve Rotary Parts Washers. Delivering exceptional cleaning power while promoting safer, more sustainable operations, it helps organisations reduce costly compliance requirements for emissions, disposal, and workplace safety.

Features:

-

Australian-made with 100% active ingredients for maximum cleaning performance

-

Improves wastewater compliance and is septic-system safe

-

Effectively removes grease, oils, and soils from industrial components

-

Non-caustic and low allergenic for enhanced worker safety

-

Rust-inhibiting properties to protect cleaned parts

-

No special storage or handling requirements

Recommended uses:

Perfect for workshops and industrial facilities cleaning:

-

Automotive, mining, and heavy equipment components

-

Engine and machine parts

-

Aerospace and defence maintenance items

-

Any parts requiring powerful, non-caustic cleaning

-

Purasolve Surface Prep is a safer alternative for preparing surfaces for painting and welding to remove contaminants. It has a low flash point and low vapour pressure compared to Acetone, MEK and other solvents. Features:

- High-Tech Cleaning Compound

- Cleans Surfaces for Painting & Welding

- Developed to replace MEK, Acetone and other Dangerous Solvents

- Non-Explosive

- Slow Evaporating

- Safe to Use, Store and Dispose of

- Improved User Safety & Comfort

- Surface preparation prior to painting

- Cleans surfaces in preparation for welding

- Removing oil, grease, glue & other residues

- Cleaning hard surfaces

Purasolve Weapons Cleaner is a fully recyclable, low vapour, benzene free, high purity hydrocarbon degreasing solvent for use in parts washers and for metal cleaning. Features:

- High-Tech Weapon and Gun Washing Solution

- Fully Recyclable

- Developed to Replace Dangerous Solvents for Weapons and Gun Cleaning

- Non-Flammable and Non-Explosive

- No Bacteria or Enzymes

- Low Odour

- Improves Worker Health & Safety

- Reduced PPE requirement

- Weapons cleaning systems

- Gun Cleaning

- Rifle Cleaning

- Metal Cleaning

- Weapons wipe down