Actuators

Showing all 8 results

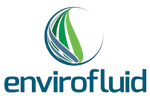

Cubic screw jacks are designed with a versatile modular system that supports both compressive and tensile loads. With a wide performance range and flexible configuration options, they provide reliable lifting, positioning, and load-handling solutions. Complementary accessories are available in both standard and customised versions to suit diverse application needs.

Features:

-

Load capacities ranging from 1,100 lbf to 112,000 lbf

-

High- and low-speed worm gear drive options

-

Translating and rotating (traversing nut) configurations

-

Self-locking ACME screw for safety and reliability

-

Standard and customisable end fittings, mounting options, and drive shaft/motor interfaces

-

Available in anti-rotation and anti-backlash versions

Recommended Uses:

-

Lifting and lowering heavy loads

-

Industrial machinery and automation systems

-

Positioning and adjustment in manufacturing equipment

-

Material handling solutions

-

Applications requiring precise linear motion with high load capacity

-

The VARIOLine actuator is a fully integrated linear drive system built on a robust aluminium profile with ball screw drives and an internal ball bearing guidance system. Designed for smooth force transfer and high precision, it provides an economical and reliable solution for a wide range of linear motion applications.

Features:

-

Extruded aluminium frame design for strength and durability

-

Two frame sizes to suit different applications

-

Thrust capacity up to 787 lbf

-

Travel speeds up to 1.5 m/sec (59 in/sec)

-

Acceleration up to 65.6 ft/sec²

-

Positional repeatability of ±0.001 in.

-

Ideal for Z-axis pick-and-place applications

-

Customisable stroke lengths and motor adaptations

-

Made in the U.S.

Recommended Uses:

-

Pick-and-place automation (Z-axis)

-

Industrial assembly systems

-

Manufacturing and material handling equipment

-

Precision positioning applications

-

General linear motion requirements

-

Victory A-Series Food Grade Actuators are engineered for performance in demanding environments such as food production, packaging, and pharmaceutical manufacturing. With robust materials, ingress protection, and food-safe components, they provide precise, reliable motion control while meeting industry hygiene standards.

Features (FG1 Option):

-

Anodized aluminium body with food-grade epoxy coating

-

300 series stainless steel inner ram and rod-ends

-

IP67 ingress protection against liquids and particulates

-

Food-grade rod wipers and seals

-

Infinitely adjustable proximity limit sensors

-

Predictable motion with reliable L10 life and maintenance intervals

-

Available across the full Victory A-Series line

-

Made in the U.S.

Features (FG2 Option):

-

Full 300 series stainless steel exterior construction

-

IP67 ingress protection against liquids and particulates

-

Food-grade rod wipers and seals

-

Infinitely adjustable proximity limit sensors

-

Suitable for caustic and washdown environments

-

Predictable motion with reliable L10 life and maintenance intervals

-

Available across the full Victory A-Series line

-

Made in the U.S.

Recommended Uses:

-

Food production equipment

-

Food packaging systems

-

Pharmaceutical manufacturing

-

Hygienic processing environments

-

Applications requiring corrosion resistance and washdown protection

-

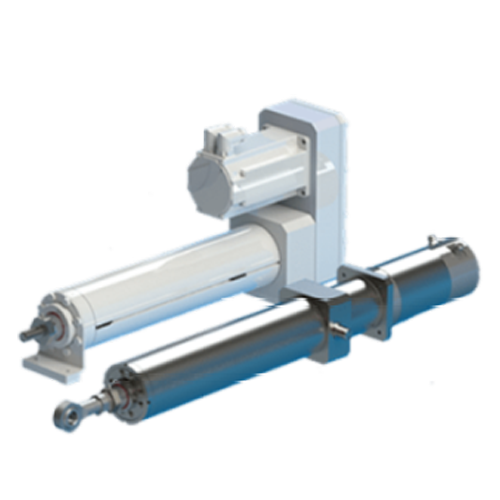

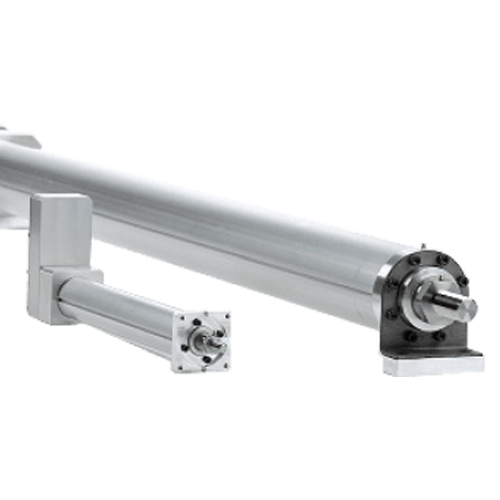

Victory A-Series actuators are built for performance and versatility, offering a clean, efficient, and precise alternative to hydraulic and pneumatic systems. With flexible screw configurations, heavy-duty design, and Hunt’s engineering expertise, these actuators deliver superior thrust, speed control, and programmability—even in harsh or contaminated environments.

Features:

-

Configurable with ball screws, roller screws, or ACME screws for unique load, speed, and duty cycle requirements

-

Internal anti-rotation rod design prevents load/tooling rotation

-

Long ram guide bearing for smooth extension and retraction

-

Wiper and seal system protects against liquid and particle ingress

-

Chrome-plated or stainless steel inner ram for corrosion resistance

-

Screw support bushing reduces vibration, improves dynamic performance, and minimises noise

-

High-capacity angular contact bearings for long life and high thrust capacity

-

Bumpers to safeguard internal components from minor over-travel

-

Multiple mounting options for pivoting or rigid applications

-

Parallel motor mounting option reduces length and allows rear clevis mounting

-

Central rod-end lube port simplifies maintenance

-

Aluminium exterior construction reduces weight and cost

-

Adjustable position sensors with dual T-slots for flexible placement

-

Flexible motor adaptation for most motor types

-

Stroke lengths up to 1,524 mm (60 in.) in 1 mm increments

-

Capable thrust loads up to 11,865 lbf

-

Available in food-grade and full stainless steel designs

Recommended Uses:

-

Military and defence equipment

-

Manufacturing and automation systems

-

Heavy-duty tooling operations

-

Food-grade processing equipment

-

Harsh or contaminated environments

-

Applications requiring high thrust and precise control

-

WH (SPEEDLine) Linear Units

The WH (SPEEDLine) series provides high-performance linear motion solutions for single-axis applications, with the flexibility to combine into two- and three-dimensional (X-Y-Z) systems. Featuring a lightweight, compact design with high load ratings, these units are especially effective for Z-axis applications requiring speed, precision, and durability.Features:

-

Maximum speed up to 10 m/s (33 ft/s)

-

Acceleration up to 40 m/s² (131 ft/s²)

-

Repeatability of ±0.05 mm (0.002 in.) under high feed forces

-

Maximum feed force of 5,000 N (1,124 lbf)

-

Payload capacity up to 9,300 N (2,090 lbf)

-

Moment load capacity up to 930 Nm (209 lbf) on carriage

-

Steel-reinforced belt drive for strength and reliability

-

Rubber wipers protect the linear guide from debris

-

Centralised lubrication system for reduced maintenance

-

Lightweight, space-saving construction

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed automation systems

-

Multi-axis (X-Y-Z) motion applications

-

Pick-and-place and handling systems

-

Precision Z-axis operations

-

Industrial assembly and packaging equipment

-

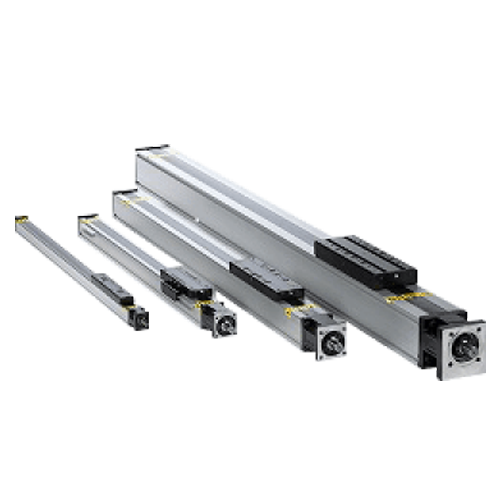

The WM (POWERLine)—formerly Wiesel POWERLine—features an advanced internal guide system with circulating ball bearings on hardened steel rails. Paired with a precision drive screw, it delivers a balanced solution of power, speed, and accuracy for demanding linear motion applications.

Features:

-

Maximum speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability up to ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Payload capacity up to 6,000 N (1,348 lbf)

-

Moment load capacity up to 600 Nm (134 lbf) on carriage

-

Compact guide and carriage configuration (-370 option)

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports reduce whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

High-precision automation systems

-

Industrial assembly and handling applications

-

Multi-axis linear motion solutions

-

Packaging and processing equipment

-

Long-stroke, high-speed linear drive systems

-

The WM (POWERLine) ZRT—formerly known as Wiesel POWERLine—combines the high travel speeds of a toothed belt drive with the robust, fully integrated ball bearing guide of the POWERLine® series. The -370 models feature a shorter guide system and compact power bridge, delivering powerful performance at a more economical price point.

Features:

-

High-speed toothed belt drive with steel reinforcement

-

Integrated ball-bearing guide system for higher moment load handling

-

Patented self-adjusting sealing cover strip protects against material intrusion

-

Compact -370 option for cost-effective performance

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed linear motion applications

-

Multi-axis automation systems

-

Packaging and assembly equipment

-

Industrial handling systems

-

Environments with potential debris exposure

-

The WV (DYNALine) series—an optimised version of the POWERLine screw-driven rodless actuators—delivers superior moment load capabilities for demanding applications. By coupling primary drive elements with external linear guides, the DYNALine ensures stability and precision, even at high speeds and long stroke lengths.

Features:

-

Maximum travel speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability of ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Dual pre-tensioned ball nuts for higher rigidity and accuracy

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports prevent whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

Applications requiring extremely high moment load capacity

-

Long-stroke, high-speed linear motion systems

-

Heavy-duty industrial automation

-

Precision assembly and material handling equipment

-

Multi-axis systems with demanding load requirements

-