Fairbanks Morse Defense

Showing 97–100 of 100 results

Similar in function to capstans, winches incorporate a rotating drum that also allows rope or cable stowage. FEC furnishes a variety of Navy-standard winches in accordance with build-to-print NAVSEA drawings, including:

-

Gypsy winches

-

Saddle winches

-

Spanwire winches

-

Barricade winches

-

Stern dock winches

-

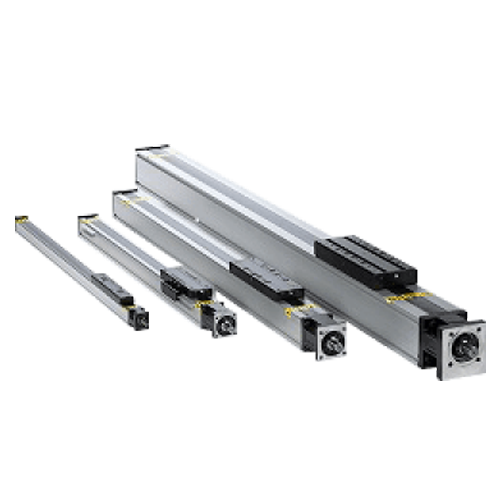

The WM (POWERLine)—formerly Wiesel POWERLine—features an advanced internal guide system with circulating ball bearings on hardened steel rails. Paired with a precision drive screw, it delivers a balanced solution of power, speed, and accuracy for demanding linear motion applications.

Features:

-

Maximum speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability up to ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Payload capacity up to 6,000 N (1,348 lbf)

-

Moment load capacity up to 600 Nm (134 lbf) on carriage

-

Compact guide and carriage configuration (-370 option)

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports reduce whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

High-precision automation systems

-

Industrial assembly and handling applications

-

Multi-axis linear motion solutions

-

Packaging and processing equipment

-

Long-stroke, high-speed linear drive systems

-

The WM (POWERLine) ZRT—formerly known as Wiesel POWERLine—combines the high travel speeds of a toothed belt drive with the robust, fully integrated ball bearing guide of the POWERLine® series. The -370 models feature a shorter guide system and compact power bridge, delivering powerful performance at a more economical price point.

Features:

-

High-speed toothed belt drive with steel reinforcement

-

Integrated ball-bearing guide system for higher moment load handling

-

Patented self-adjusting sealing cover strip protects against material intrusion

-

Compact -370 option for cost-effective performance

-

Manufactured in the U.S.

Recommended Uses:

-

High-speed linear motion applications

-

Multi-axis automation systems

-

Packaging and assembly equipment

-

Industrial handling systems

-

Environments with potential debris exposure

-

The WV (DYNALine) series—an optimised version of the POWERLine screw-driven rodless actuators—delivers superior moment load capabilities for demanding applications. By coupling primary drive elements with external linear guides, the DYNALine ensures stability and precision, even at high speeds and long stroke lengths.

Features:

-

Maximum travel speed up to 2.5 m/s (8.2 ft/s)

-

High repeatability of ±0.01 mm (0.0004 in.)

-

Maximum feed force of 12,000 N (2,698 lbf)

-

Dual pre-tensioned ball nuts for higher rigidity and accuracy

-

Self-sealing protective cover strip for debris protection

-

Travelling screw supports prevent whip at high speeds and extended lengths

-

Manufactured in the U.S.

Recommended Uses:

-

Applications requiring extremely high moment load capacity

-

Long-stroke, high-speed linear motion systems

-

Heavy-duty industrial automation

-

Precision assembly and material handling equipment

-

Multi-axis systems with demanding load requirements

-