Fairbanks Morse Defense

Showing 49–60 of 100 results

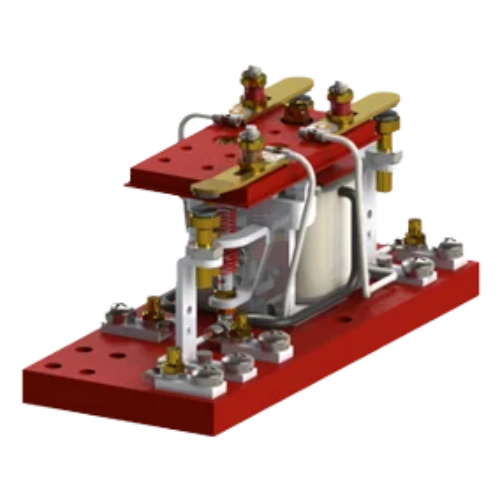

Series N130 Magnetic Relays are designed for reliable performance in applications where pilot or control circuits must be repeatedly established and interrupted. Available in multiple pole configurations for both AC and DC operation, these auxiliary control relays provide dependable switching and long service life in demanding environments.

Features:

-

Arc blowout option for improved arc suppression

-

Manufactured across all 3 QPL designs: Ward Leonard, GE, and Cutler Hammer

-

Built for durability and consistent operation in critical applications

Recommended Uses:

-

Pilot and control circuits

-

Defence and naval electrical systems

-

Industrial automation requiring repeated circuit switching

-

Applications needing AC or DC auxiliary relay control

-

Manual starters are built for reliability and continuous duty, providing decades of service in demanding environments. Designed for flush panel mounting or surface mounting with drip-proof enclosures, these starters feature integrated overload protection and low-voltage release functionality, ensuring dependable motor control in high-shock and high-vibration conditions.

Features:

-

Thermostatic bimetal overload protection

-

Low-voltage release (contacts remain closed under low voltage, restart on power return)

-

Cable entry from top or bottom for flexible installation

-

Compact package for basic motor starter and protection

-

Compliant with MIL-DTL-2212 specification

-

Master switches provide remote control of magnetic starter applications and are designed for long-lasting reliability in demanding environments. Available in multiple configurations, they support up to 20 circuits and comply with MIL-DTL-2212 standards for military-grade performance.

Features:

-

Available in master, limit, pushbutton, and rotary selector variants

-

Spring-returning or maintaining contact options

-

Watertight and non-watertight designs available

-

Compliant with MIL-DTL-2212 specification

-

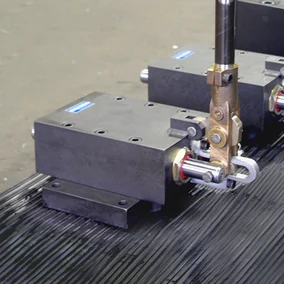

Brand: Hunt Valve Hunt Valve’s new Mega-Flo C Descale Valves are the longest lasting plunger-style descale valves available. This ultra-durable plunger-style descale valve saves customers 33% on the total cost of ownership over competitors’ poppet style valves. The savings is based on the initial purchase price and maintenance requirements over the first three years of service, then a 50% reduction in maintenance costs thereafter. Why Hollow Plunger Technology delivers better durability Zero Leakage and extended durability: - Since the UHMW plunger seals create a zero leakage seal, internal component damage from water jetting is eliminated. - Since the UHMW plunger seals are only directly exposed to the high velocity water flow for 1-2 seconds per shift, wear is minimized. - Since the UHMW plunger seals are pushed away from the surface of the plunger when shifting the valve, wear is minimized resulting in longer service life and improved contamination tolerance. Product Features: - State-of-the-art valve based on Hunt’s proven core plunger technology. - Advanced materials used in Hunt’s proven integral pressure breakdown design. - Forged housing designs are treated for corrosion and wear protection to extend the service life of the housing. - Stainless Steel Housing Liner can be replaced in the field. - Upgraded cylinder design for less corrosion, wear and friction due to the following: Nitrocarburized piston rod and tie-rods. Low friction urethane piston and rod seals. 60 RC hard anodized cylinder bore. - Low-turbulence flow plunger design. - Plunger contained in the pressure vessel for safety. - Staggered flow slots provide gradual acceleration and deceleration of flow during plunger shifting to prevent water hammer. - Proximity switch or Transducer options for position feedback. - Isolated air actuator, kept away from the high-pressure fluid. - Anti-extrusion seals without grease requirements. - Seal is pushed away from the plunger by the fluid pressure during shifting to prolong life. - Sealing surface is NOT exposed to the water flow path when valve is open or closed. Mega-Flo Cartridge-Style Plunger Assembly Extend the life of your existing valve installation by replacing your old-style cartridge. The Mega-Flo C cartridge assembly is a drop-in fit to the existing Mega-Flo A or B installation for easy field upgrade capability. It offers the benefits of the Mega-Flo C enhancements without having to replace the entire valve system. The cartridge is a 40% cost savings versus purchasing a complete new valve. Electromechanical Actuator for Precision Control Do you have cooling issues with your strip from continuous header pre-fill flow? An electromechanical actuator shifts the plunge from the pre-fill flow position to the full off position to reduce this problem. The new linear actuator design provides precision control. Besides solving your cooling issues, this actuator: - Provides the necessary prefill to prevent water hammer and resulting header damage. - Eliminates the maintenance and reliability concerns of operating an external high-pressure solenoid-operated prefill control valve. - Relieves safety, maintenance and reliability issues of operating a low-pressure prefill system. - Offers flexibility to shut off the prefill flow when not required, thus providing increased flow and pressure available for descaling to the system or a significant energy cost savings if one pump can be shut-down by eliminating all of the continuous prefill lines in the system.

Brand: Hunt Valve Hunt Valve’s Mega-Flo C Descale Valves (2-, 3- and 4-inch models) are known around the world for its innovative design and quality engineering. This fast-acting, smooth-shifting product consistently provides high-pressure water when needed. Using the world’s most advanced ceramic material, the valve’s radial-ported plunger is precision-machined. With a radial-ported plunger design, the seal is pushed away from the plunger by the fluid pressure during shifting, offering a significantly longer seal life. In addition, the staggered flow slots provide gradual acceleration and deceleration of flow during plunger shifting to prevent damage to the piping system from velocity shock (water hammer). The valve’s inherent wear-resistant design and stringent material specification help ensure a long service life for this critical component. In fact, the valve’s smooth-shift operation helps prolong the life of all components in the descaling system. Product Features: - Zero leakage. - Fail-safe, open design. - Electronically controlled. - Easy and positive position monitoring.

Brand: Hunt Valve High durability equipment designed to withstand harsh operating environments and hard wear. The Hunt Mill Duty (SPV) Descale Valve is a true mill duty valve design that incorporates robust construction and the world’s most advanced materials to deliver ultimate durability in a mill duty descale environment. Our poppet descale technology addresses the common issues associated with valves commonly available for descale applications: - Pilot Valve Reliability and Durability. - Seat Wear and Erosion. Mill Duty Pilot Valve Cost Savings The SPV series descale valve delivers higher durability than any other system’s piloted design thanks to our stainless steel spindle technology. This feature delivers a 15% Total Cost of Ownership (TCO) reduction compared to other media piloted designs over a three-year period. Our pneumatic solenoid pilot valve design results in additional maintenance cost savings. It is manufactured from stainless steel with hardened seats to provide total corrosion resistance on your system. This valve delivers 100% shifting reliability due to the high force solenoid air pilot operation. This removes the possibility of sticking due to varnishing or contamination. The SPV pilot valve delivers a 15% TCO (Total Cost of Ownership) savings over a three-year period. Mill Duty Cartridge Offers Maximum Durability Hunt’s poppet design incorporates Heat Treated Stainless Steel Cartridge components with optional seat configurations using soft seat, hardened stainless or Hardfaced seats for maximum durability. Mill Duty Housing Hunt’s poppet design incorporates salt-bath nitrocarburizing of the housing and cap to deliver mill duty corrosion and wear resistance in the standard configuration and an option for full stainless designs for the most demanding environments. Additional Options The SPV series valve is available with a variety of options to suit application preferences including: - Gag devices for maintenance shut-off and lockout. - Proximity switches. - Integral header pre-fill control and pressure breakdown.

Brand: Hunt Valve The Hunt Mill Duty (SPV) Descale Valve for descaling pump bypass applications incorporates robust construction and the world’s most advanced materials to deliver ultimate durability in a mill duty descale environment. This Mill Duty Pump Bypass Valve defaults to an open valve position. Our poppet descale technology addresses the common issues associated with valves commonly available for descale applications: - Pilot Valve Reliability and Durability. - Seat Wear and Erosion. Mill Duty Cartridge Offers Maximum Durability Hunt’s poppet design incorporates Heat Treated Stainless Steel Cartridge components with both soft and hard seat configurations for maximum durability. In addition, we offer optional hardfaced configurations for the ultimate in corrosion and wear resistance. Mill Duty Housing Hunt’s poppet design incorporates salt-bath nitrocarburising of the housing and cap to deliver mill duty corrosion and wear resistance.

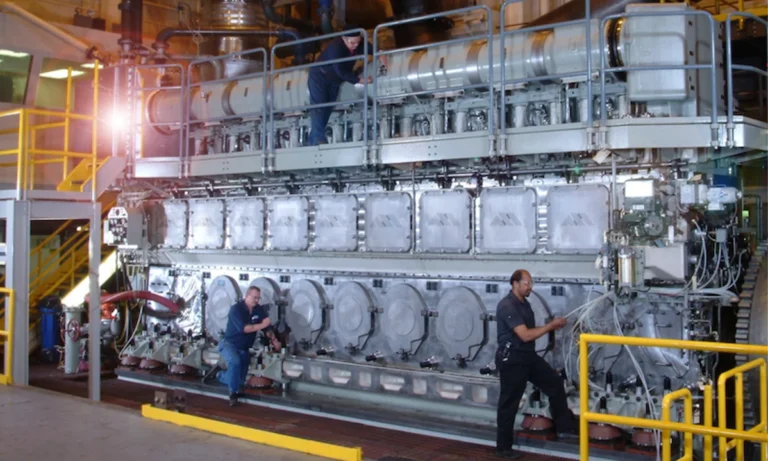

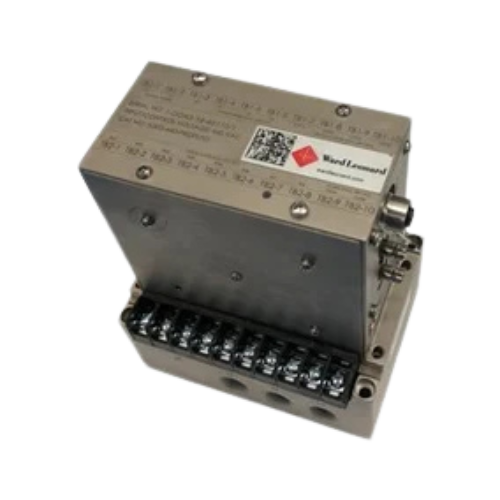

With more than 2,000 designs available, Fairbanks Morse Defense and Ward Leonard deliver controllers engineered for durability, reliability, and long service life. Built for dedicated high-shock, high-vibration, and high-abuse environments, these controllers are trusted by maritime vessels and defence applications worldwide. Every unit is manufactured and tested in-house to meet the U.S. Department of Defense’s most stringent specifications.

Features:

-

Performance ratings from size 0 to size 7

-

Extensive catalogue of 2,000+ proven designs

-

3D modelling for customised solutions

-

Built and tested to MIL-DTL-2212 specification

-

Engineered for decades of dependable performance

Recommended Uses:

-

Maritime vessels and shipboard systems

-

Defence and naval applications

-

High-shock and high-vibration environments

-

Industrial and mission-critical systems requiring long-life controllers

-

Brand: Hunt Valve Hunt Valve’s MV0 Valve Series Directional Control Valves are designed for the central hydraulic system within the rolling mill. The MV0 Series is an upgrade of the original MSA valve line (V03 & V05 Valve). These valves were specifically designed for high water-based fluids. With two-, three- and four-way operation as well as two- and three-position configuration, these valves are highly versatile for a variety of mill line applications. Hunt Valve has continually upgraded this technology to make the valves easier to use. MV03 & MV05 Valves Hunt Valve’s MV03 & MV05 Directional Valves are manufactured with the high-quality design features required for the severe duty cycles of the steel mill industrial descale systems. The V03 & V05 Series, the forerunner of the MV03 & MV05, has proven to be one of the most reliable valves in the world for severe mill duty applications. The M in the product name stands for “modular.” We upgraded this line of valves to include modular cartridge units that significantly reduce spare part requirements and streamline the maintenance procedure for the end user. The MV03 valves are rated for 3000 psig while the MV05 valves are rated for 5000 psig.

Ward Leonard Noise Quiet Motors are designed for submarine operations, reducing vessel detectability while powering critical pumps and compressors on Los Angeles, Ohio, and Virginia Class fleets. Compact, shock- and vibration-proof designs allow installation in confined spaces.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne noise performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-

The Novo Motor line represents Fairbanks Morse Defense’s commitment to innovation for maritime defense. Built for Surface Navy vessels, these AC induction motors feature 12 frame sizes and a wide range of configurations for maximum customisation and economy. Manufactured under ISO-9001 certification, they are designed to withstand extreme impacts and meet MIL-DTL-17060 requirements.

Key Features

-

Modular design for flexible customisation

-

Commonality of parts

-

Multiple mounting configurations, speeds, and enclosures to meet shipboard needs

-

Built to Navy MIL-Spec standards: MIL-DTL-17060 Rev. G Amendment 1

-

CBM+ ready and VFD compatible

Advantages

-

High reliability

-

Cost-effective and economical

-

Fairbanks Morse Defense and Ward Leonard overload relays are engineered for mission-critical applications in the harshest environments. Built to withstand high shock and vibration, these solid-state relays provide dependable motor overload protection while meeting stringent NAVSEA and MIL-Spec requirements. With advanced monitoring capabilities and support for multiple communication protocols, they deliver performance, reliability, and long service life.

Features:

-

Motor overload protection function

-

Available in thermal, AC, and DC magnetic set and reset versions

-

Magnetic inverse time delay type, self-repeat operation

-

Increased monitoring capability while reducing controller size and weight

-

Support for Modbus, Profibus, and Ethernet protocols (on select models)

-

Built to MIL-R-2033 and MIL-DTL-2212 specifications

Recommended Uses:

-

Naval compressors and shipboard motor systems

-

Defence and naval electrical protection systems

-

Industrial applications requiring shock- and vibration-resistant relays

-

Harsh environments where reliable overload protection is critical

-