Water Treatment & Purification

Showing all 8 results

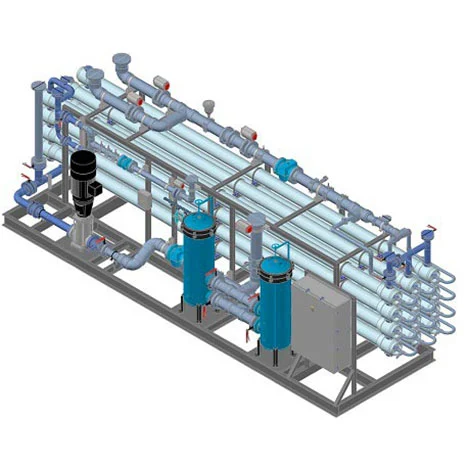

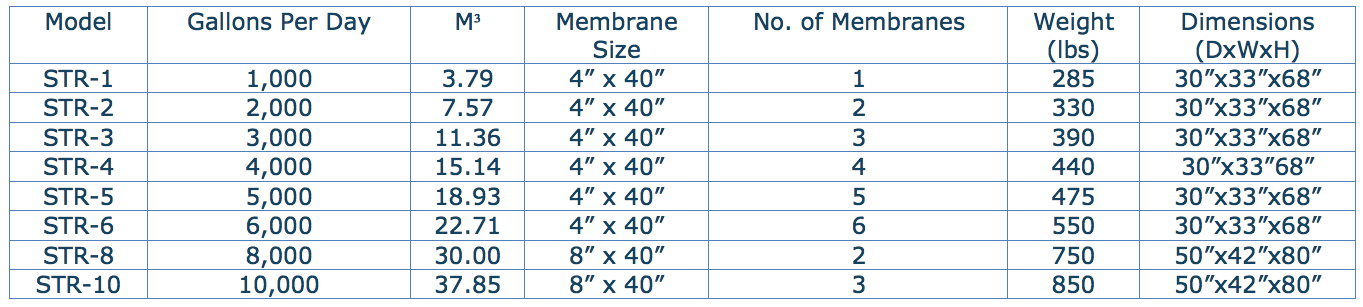

Our two lines of Brackish Water Reverse Osmosis systems have water production capacities ranging from 150 GPD up to 432,000 GPD. Custom units are available upon request.

Fairbanks Morse Defense and Maxim’s equipment capabilities extend to custom piping assemblies. Materials of construction include 90/10 Cu/Ni, 70/30 Cu/Ni, Monel, 304 Stainless Steel, 316 Stainless Steel, Super Duplex Stainless Steel, Titanium and other materials as needed. We are qualified for the following:

- S9074-AR-GIB-010/278: Requirements For Fabrication Welding & Inspection, And Casting Inspections And Repair For Machinery, Piping, And Pressure Vessels

- T9074-AS-GIB-010/271: Requirements For Non-Destructive Testing Methods

- S9074-AQ-GIB-010/248: Requirements For Welding And Brazing Procedure And Performance Qualification

- MIL-STD-278: Welding and Casting Standard

- MIL-STD-1689: Fabrication, Welding and Inspection of Ship Structure

- MIL-STD-2035: Nondestructive Testing Acceptance Criteria

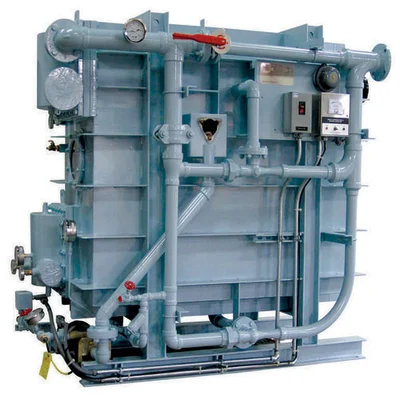

The electronics cooling system is an electrically powered system used to cool, circulate, filter, purify and monitor the demineralised water used to cool various electronic equipment. It is a self-contained, modular, unit that controls the temperature of the demineralised water system by using seawater as the cooling medium. Maxim manufactures the electronics cooling system for DDG 51 Flight III Guided Missile Destroyers. The electronics cooling system successfully completed Environmental Qualification Testing (EQT), including: Grade A Heavyweight Shock; Vibration Type I and Type II; EMI; Airborne & Structureborne Noise.

Fairbanks Morse Defense and Maxim have been designing and manufacturing heat exchangers for water treatment and water handling equipment for over 70 years. Maxim offers shell & tube and plate-type heat exchangers.

- Material of construction include, but are not limited to:

- 90/10 CuNi

- 70/30 CuNi

- Titanium

- Other materials as may be required.

- For 90/10 CuNi seamless tubing:

- 5/8 – 18 BWG to 20 BWG

- 3/8 – 20 BWG to 22 BWG

- Other sizes as may be required.

- Currently, Maxim manufactures tube bundles up to 34” x 27” x 88”. The tube bundle pictured below is 32” Dia. X 56”, weighing 1,400 lbs. Maxim has the ability to manufacture heat exchangers that exceed this size based on the technical specifications provided.

- Material of construction include, but are not limited to:

Our heat recovery evaporators utilise waste heat to make high quality potable water from seawater, brackish water or contaminated feed water sources. The HJ Series is made of five models, with fresh water capacities ranging from 192 to 3,000 gallons per day.

- Perfect for pleasure boats or small work boats, yachts, cruisers, tug boats, fishing boats, survey vessels, offshore drilling and production platforms, offshore supply vessels, USCG and USN vessels, and many other applications.

- Utilizes waste heat, reducing operating costs since little new energy generation is needed.

- Environmentally friendly since energy is conserved and there are no membranes or filters to replace or dispose of.

Our heat recovery evaporators utilise waste heat to make high quality potable water from seawater, brackish water or contaminated feed water sources. The TCF Series is made up of five models, with fresh water capacities ranging from 3,700 to 15,000 gallons per day.

- Perfect for larger cruisers, tugs, fishing boats, survey vessels, and offshore production platforms.

- Utilizes waste heat, reducing operating costs since little new energy generation is needed.

- Thermo circulation design minimizes scaling and lowers maintenance costs.

- Environmentally friendly since energy is conserved and there are no membranes or filters to replace or dispose of.

Fairbanks Morse Defense and Maxim manufacture resilient mount snubbers to Navy Standard Drawing 112-1889944 for use in conjunction with equipment being furnished by Maxim for DDG 51 Flight III. Maxim has developed the capabilities to manufacture resilient mount snubbers, for machinery mounts, to the following Navy Standard Drawings:

- 112-1889946

- 112-1889949

- 112-1889943

- 112-1889942

- 112-1889944