Fairbanks Morse Defense

Showing 61–72 of 101 results

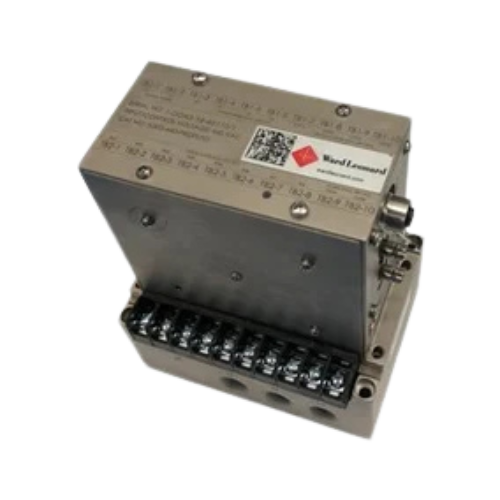

Fairbanks Morse Defense and Ward Leonard overload relays are engineered for mission-critical applications in the harshest environments. Built to withstand high shock and vibration, these solid-state relays provide dependable motor overload protection while meeting stringent NAVSEA and MIL-Spec requirements. With advanced monitoring capabilities and support for multiple communication protocols, they deliver performance, reliability, and long service life.

Features:

-

Motor overload protection function

-

Available in thermal, AC, and DC magnetic set and reset versions

-

Magnetic inverse time delay type, self-repeat operation

-

Increased monitoring capability while reducing controller size and weight

-

Support for Modbus, Profibus, and Ethernet protocols (on select models)

-

Built to MIL-R-2033 and MIL-DTL-2212 specifications

Recommended Uses:

-

Naval compressors and shipboard motor systems

-

Defence and naval electrical protection systems

-

Industrial applications requiring shock- and vibration-resistant relays

-

Harsh environments where reliable overload protection is critical

-

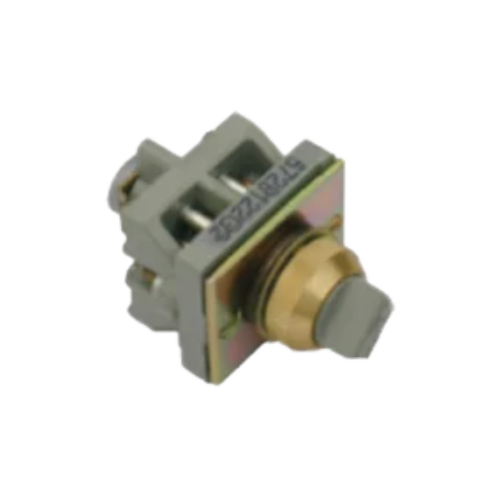

Panel mounted push buttons are designed for continuous duty in harsh environments, offering watertight and oiltight protection to ensure decades of reliable service. Built to withstand high shock, vibration, and abuse, they provide dependable control for panels, remote stations, and motor controllers.

Features:

-

Momentary closure or open operation

-

Normally Open (NO) or Normally Closed (NC) configurations

-

Up to 2-pole capability

-

Durable design for long service life

-

Panel mounted switches are a reliable solution for maintained contact switching of control circuits. Designed for durability, they offer multiple configuration options and are built to withstand demanding environments while complying with MIL-DTL-2212 standards.

Features:

-

Available in master, limit, pushbutton, and rotary selector variants

-

Spring-returning or maintaining contact options

-

Watertight and non-watertight designs available

-

Compliant with MIL-DTL-2212 specification

-

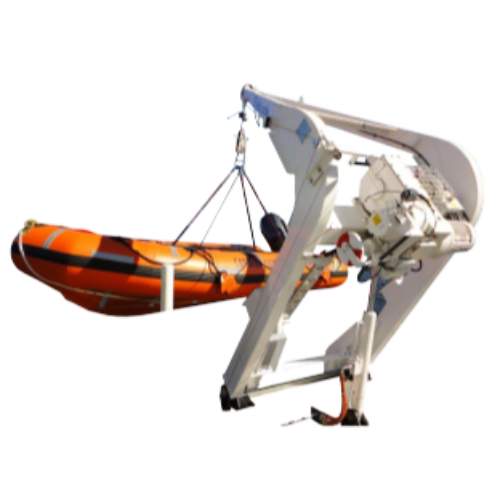

The PIV 1.0 and PIV 1.6 have safe working loads (SWL) of up to 1,000 kg (2,204 lbs) and 1,600 kg (3,527 lbs) respectively. These davits are suitable for integration into both new constructions and existing vessels, with the PIV 1.0 offering a total davit weight of 730 kg.

Meeting the latest SOLAS requirements, the davits are fitted with an anti-pendulum frame that interfaces with the rescue boat and can be supplied with optional features such as:

-

Falls tensioning

-

Shock absorbers

-

RIB docking frames

-

Integrated boat stowage

-

Davit head lighting

-

Integrated diagnostic/system monitoring

-

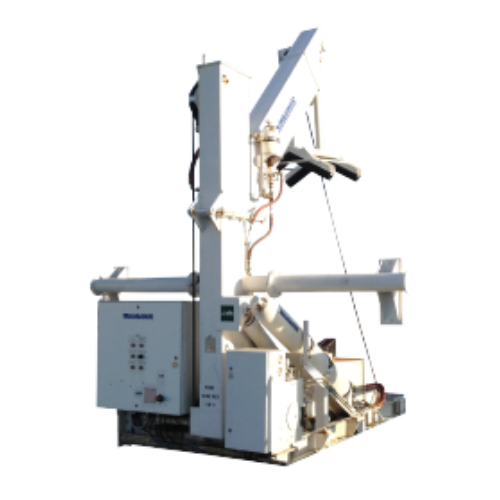

The PIV 3.0 / PIV 4.0 davit is a fully self-contained, palletized system with a safe working load of up to 4,000 kg (8,818 lbs), making it ideal for the operation of RIBs in the 5.5 to 7.5 m range.

Designed to minimise installation impact on both new builds and existing vessels, the davit features an integrated power pack and accumulators that are factory-installed with the complete electrical system.

Integrated into the davit, the boat stowage device can be configured to suit most hull forms. Performance can be further enhanced with optional all-electric/electronic falls tensioning, a shock absorber, and an anti-pendulum RIB docking frame.

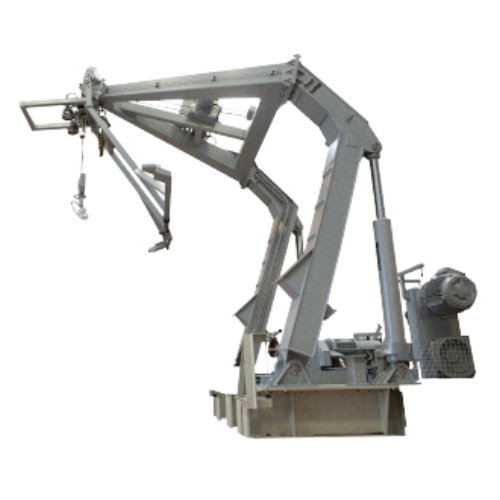

The PIV 3.6E is a custom-application davit that provides a lightweight system designed to meet both shock and EMI requirements. Its aluminium A-frame construction incorporates several weight-saving features, with components selected to handle the high duty cycle of mission requirements while addressing the weight sensitivity of combatant ship designs.

The PIV 3.6E davit is supplied with variable-speed power hoisting/lowering and luffing, along with adjustable falls tensioning. The modular design includes bolting interfaces for ease of installation and full manual operation for all principal functions. Integrated boat chocks and an RHIB docking frame are also included.

Options include:

-

Fully integrated diagnostic system

-

Release hook

-

Davit head floodlights for night operations

-

Power terminal boards are one-piece designs built for use in power circuits ranging from 50 to 600 amps. Engineered for durability and reliability, they meet stringent MIL specifications to ensure long-lasting performance in demanding environments.

Features:

-

Compliant with MIL-C-2212 specification

-

Meets MIL-E-917 standards for performance and reliability

-

Brand: Hunt Valve Pre-fill valves give you on/off control of the existing descale water for pre-filling the spray headers. This prevents the shock that occurs within the descale piping system when the main descale spray valves are opened to an empty header. The pre-fill valve is installed as a bypass around the descale spray valve. The versatility of our 2-inch and 3-inch descale spray valves make them the perfect choice for use as header pre-fill valves, Descale Valves and Pre-Fill valves. Mega-Flo B (2- and 3-inch Models) Hunt Valve’s Mega-Flo B 2-inch and 3-inch control valves offer a reliable, cost-effective means for low-flow descale spraying or descale header pre-filling. Our experience with field application problems associated with the fully mechanical protection valves of other manufacturers has led us to adapt and customize our Mega-Flo B products to fit this critical application. Product Features - Zero leakage - Electronically controlled - Easy and positive position monitoring

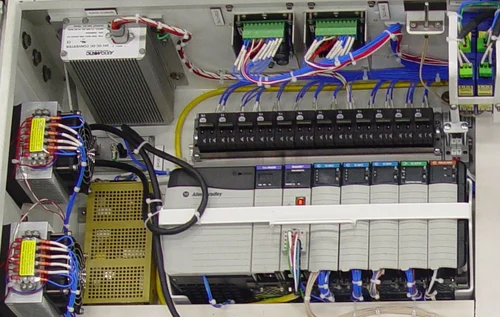

Today many shipboard systems have increased automation requiring digital controls, solid state relays in lieu of electromechanical relays, and invoke PLCs for increased service life, reliability, flexibility, and compatibility with newer technology. FEC has a solid background incorporating PLCs in weapons and material handling systems, particularly in the elevator and conveyor arena.

Brand: Hunt Valve Check valves are required at the pump discharge lines to automatically prevent the backflow of descale water from the active pump units into a standby pump or a pump in the bypass mode. At Hunt Valve, our check valves are built with hardened seats to withstand the frequency of operation without failure. They are manufactured with the high-quality design features required for the severe duty cycles of the steel mill industrial descale system. The poppet design is engineered for reliability and longevity in the dirty descale water environment.

Ward Leonard pump motors are engineered to endure harsh naval environments, reliably powering pumps for brine, graywater, ground food waste, cooling, bilge, firefighting, and more.

Key Performance Ratings

-

1/16 to 350 HP

-

2–16 pole speeds

-

440V / 3 / 60 Hz

-

Open and closed motor enclosures

-

Service A and C applications

-

Grade A and B shock & vibration capable

Key Features

-

Class F sealed insulation system

-

Vacuum pressure impregnation

-

Nodular iron frame construction

-

Precision bearings

-

Low structure-borne vibration performance

-

Single and multiple stator winding designs

Specifications

-

MIL-M-17060 / MIL-DTL-17060: Alternating Current Motors

-

MIL-M-17059: Fractional Horsepower Motors

-

MIL-S-901: Shock Testing

-

MIL-STD-167: Vibration Testing

-

MIL-STD-740: Noise Testing

-

MIL-STD-2037: Vacuum Pressure Impregnation

-