Fairbanks Morse Defense

Showing 13–24 of 101 results

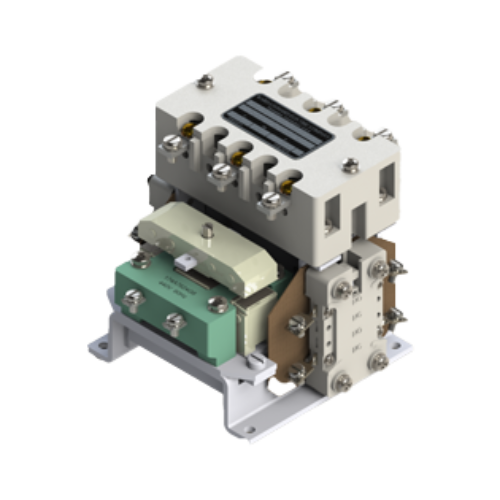

Fairbanks Morse Defense and Ward Leonard are the only manufacturers offering all three Navy QPL contactor designs, providing solutions that meet the most demanding military specifications. Built for reliability and performance, our contactors are designed to withstand mission-critical environments and comply with MIL-DTL-2212 standards.

Features:

-

Magnetic solenoid operation for dependable switching

-

Multiple configuration types to suit diverse applications

-

Flexible form factors designed to fit customer space requirements

-

Available in proprietary designs, GE designs, and Navy-standard models

-

Compliant with MIL-DTL-2212 specification (AC Control)

Recommended Uses:

-

Naval and defence power systems

-

Shipboard electrical distribution

-

Industrial and mission-critical applications requiring AC control

-

Environments requiring MIL-qualified electrical components

-

Motor controllers, operator stations, power panels, disconnect switches/panels, and junctions boxes can all be furnished by FEC in accordance with the previously mentioned electrical specifications. FEC has significant experience with electrical enclosures of all kinds and can perform the electrical design, assembly and testing required to ensure our deck machinery meets the fit, form and function desired for Navy shipboard use.

Control power transformers are designed to reduce supply voltage to 115V AC for use in control circuits of motor starters, controllers, and other electrical equipment. Built for continuous duty, they ensure safe and reliable operation in demanding environments.

Features:

-

Reliable voltage regulation for control circuits

-

Compact, durable construction

-

Designed for long service life under continuous operation

-

For decades, FEC has been the trusted supplier of complex cargo-handling systems, along with elevator and conveyor field service and spare parts for the Navy, Coast Guard, and shipbuilders.

Applications include handling palletised cargo such as missiles, bombs, and general stores. FEC is the primary supplier of the Advanced Weapons Elevator (AWE) for the Ford-class aircraft carriers and continues to support new lift systems, including the ammunition lift system for the DDG class destroyers.

Fairbanks Morse Defense and Federal Equipment Company’s crane offerings provide adaptable solutions for diverse lifting needs. From shipboard cranes designed for specialized weapons handling systems to commercial cranes suited for industrial applications, our range caters to various capacities and spans. With capabilities spanning from ¼ ton to 300 tons and spans from 5’ to 165’, our cranes are engineered for reliability and performance in hazardous environments.

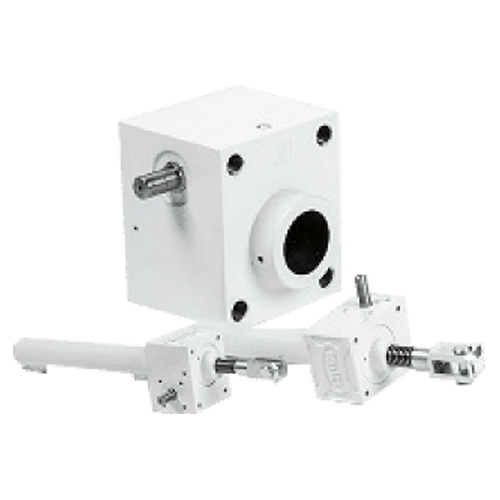

Cubic screw jacks are designed with a versatile modular system that supports both compressive and tensile loads. With a wide performance range and flexible configuration options, they provide reliable lifting, positioning, and load-handling solutions. Complementary accessories are available in both standard and customised versions to suit diverse application needs.

Features:

-

Load capacities ranging from 1,100 lbf to 112,000 lbf

-

High- and low-speed worm gear drive options

-

Translating and rotating (traversing nut) configurations

-

Self-locking ACME screw for safety and reliability

-

Standard and customisable end fittings, mounting options, and drive shaft/motor interfaces

-

Available in anti-rotation and anti-backlash versions

Recommended Uses:

-

Lifting and lowering heavy loads

-

Industrial machinery and automation systems

-

Positioning and adjustment in manufacturing equipment

-

Material handling solutions

-

Applications requiring precise linear motion with high load capacity

-

Fairbanks Morse Defense and Maxim’s equipment capabilities extend to custom piping assemblies. Materials of construction include 90/10 Cu/Ni, 70/30 Cu/Ni, Monel, 304 Stainless Steel, 316 Stainless Steel, Super Duplex Stainless Steel, Titanium and other materials as needed. We are qualified for the following:

- S9074-AR-GIB-010/278: Requirements For Fabrication Welding & Inspection, And Casting Inspections And Repair For Machinery, Piping, And Pressure Vessels

- T9074-AS-GIB-010/271: Requirements For Non-Destructive Testing Methods

- S9074-AQ-GIB-010/248: Requirements For Welding And Brazing Procedure And Performance Qualification

- MIL-STD-278: Welding and Casting Standard

- MIL-STD-1689: Fabrication, Welding and Inspection of Ship Structure

- MIL-STD-2035: Nondestructive Testing Acceptance Criteria

The davit systems excel in both military and commercial settings. Designed to meet stringent standards, our military davits ensure smooth small boat launch and recovery, while our commercial offerings adhere to BS EN ISO 9001:2015 and SOLAS regulations for reliability and compliance. With Welin Lambie, expect comprehensive and efficient davit solutions for diverse marine environments.

Strainers within a descale system should be included for each descale spray valve for the large filtration of high-pressure water (700-micron level). The strainers are installed prior to the descale spray valves to protect the internal components of the valve from large debris. At Hunt Valve, our rugged strainers can withstand the severe-duty cycles of the industrial descale systems in steel mills. These high-pressure devices are designed to avoid the plugging of descaling spray nozzles, resulting in scrap product and profit loss due to surface quality defects such as scale streaks. Strainers placed in the line with the descaling valve prevent any foreign material that’s large enough to be harmful from reaching the spray nozzles. Hunt Valve’s strainers are also used to protect the internal parts of the operating valves. All foreign particles filtered out of the stream of water passing through the strainer are stopped by the grooved rings and collect outside the strainer basket. The basket can be cleaned by removing it from the housing and spraying a jet of compressed air between the rings. Product Specifications: - The maximum working pressure for all sizes is 5,800 psi. (As the basket clogs over time, the outlet pressure will drop. This differential pressure must be monitored to avoid damage to the element and subsequent damage to other system components.) - The standard filtration rating is 711 micron; custom ratings are available to suit your nozzle requirements. - Installation is allowed in the horizontal or vertical positions. - While standard ANSI and DIN flanges are the most common, special configurations are also available.

A pressure breakdown orifice is required to control the fluid flow rate when discharging from High pressure to Low pressure requirements such as pre-filling descale headers and centrifugal pump minimum flow bypass. This orifice is located in the bypass line around the descale spray valve for Header Prefill and on the high pressure discharge side of the pump. Hunt Valve’s pressure breakdown orifices are specially designed for maximum life and ease of maintenance. These orifices are individually created to handle the pressure drop and pressure/flow rate requirements of each application. A series of heat-treated stainless steel orifice plates are used to reduce the pressure from the inlet to the outlet. Each orifice plate is designed to provide a small pressure drop, which spreads the wear throughout the components. O-rings with Teflon™ back-up rings seal the orifice plates to the stainless steel housing. A unique feature of Hunt’s design is an extended stainless steel liner located at the outlet side of the orifice assembly which protects your mating piping system from erosion due to the high-velocity turbulent flow exiting the orifice plates. At Hunt Valve, each breakdown orifice assembly is designed for the customer’s specific application, considering inlet/outlet pressure and flow requirements. The following flange connections are available: ANSI, SAE 4-bolt or DIN. Special flanges and configurations can also be designed. Pressure test ports can be included to easily monitor wear. Installation is allowed in the horizontal or vertical position. The orifice assembly is mounted between piping flanges; no mounting brackets or additional supports are required. The pressure breakdown orifice can be used in any application where the system pressure needs to be reduced at a constant rate with a constant flow. A typical descale system can include the breakdown orifice for both pump bypass and header pre-fill applications.

FEC is the leading provider of shipboard dumbwaiters for the US Navy. Available in a range of sizes, capacities, and travel lengths, these systems are installed across multiple ship classes to facilitate efficient vertical transport of small loads.

The electronics cooling system is an electrically powered system used to cool, circulate, filter, purify and monitor the demineralised water used to cool various electronic equipment. It is a self-contained, modular, unit that controls the temperature of the demineralised water system by using seawater as the cooling medium. Maxim manufactures the electronics cooling system for DDG 51 Flight III Guided Missile Destroyers. The electronics cooling system successfully completed Environmental Qualification Testing (EQT), including: Grade A Heavyweight Shock; Vibration Type I and Type II; EMI; Airborne & Structureborne Noise.