Guascor Energy

Showing all 6 results

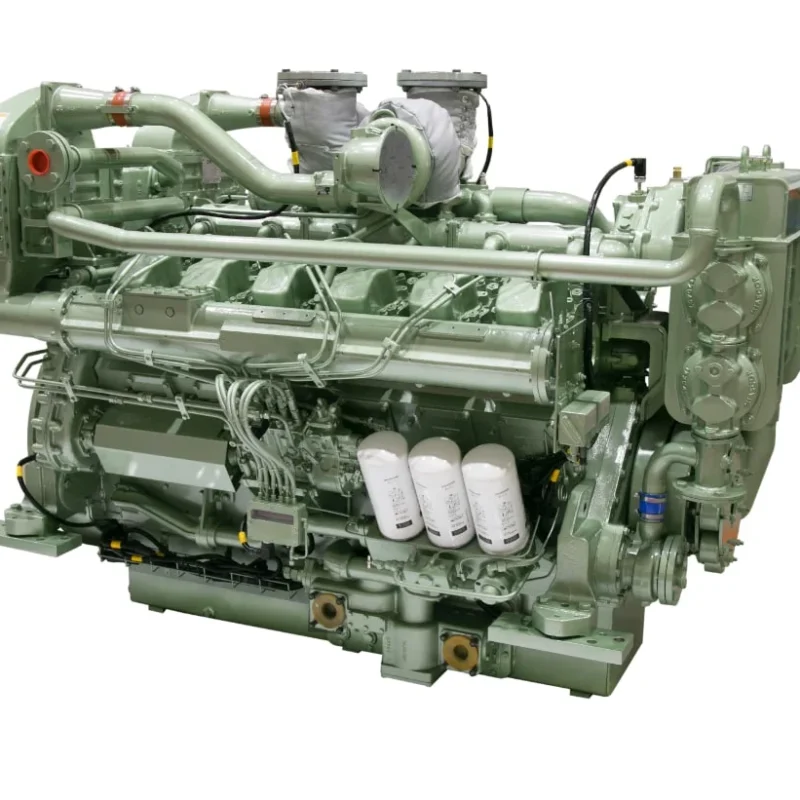

- Designed for minimal fuel consumptionMore than 50 years in this field has given Guascor Energy extensive experience that allows it to meet the most demanding working conditions for marine engines. Guascor Energy offers a complete range of propulsion and auxiliary engines powered by diesel combined with reduction gearboxes to meet the demand of any type of boat: fishing vessels, tug boats, bulk carriers, trawlers, workboats or dredges. The marine engines are also available for auxiliary purposes on board or for power generation. When working as a power generation set, there are two options available: engine powered by diesel or by gas.

Propulsion Engines

Guascor Energy offers a complete range of engines for propulsion application with power outputs between 184 kW and 1324 kWAuxiliary Engines Variable Speed

Available variable speed engines for auxiliary applications have an output from 412 kW to 1324 kWMarine Power Generation Engines and Gensets

The necessary power on board can be supplied by the Guascor Energy marine power generation engines and complete generation sets with a power output between 294 kW and 1177 kWMarine Power Generation Set (Electric Propulsion)

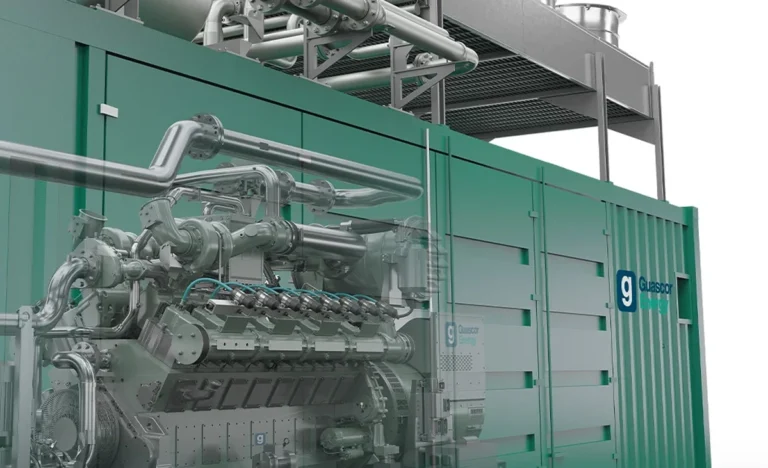

Generation Sets specifically designed for marine electrical propulsion providing reliable power in the worst scenarios. Power output between 248 and 1120 kWe at 50 and 60Hz. - High efficiency power generationA powerful new competitor in the expanding market for reciprocating engines in power generation applications, the EM Series offers best-in-class performance with excellent efficiency on a small footprint. The electronically carbureted EM Series gas engines feature the highest electrical efficiency in the industry, with low emissions from a smaller footprint. Output of the 86EM engine is 2065 kWb @ 50 Hz and when fueled with natural gas. At 60 Hz the output of the 100EM is also 2065 kWb. Unique among existing engines, the 100EM is the only direct drive solution available for the 60 Hz market.EM EnginesUncompromising performance to meet your ever-growing demands. In the world of power generation, you face plenty of challenges. If you want to successfully overcome them you need to have the best solution in place. Here’s a look at what our best-in-class solution can deliver. The best-in-class solution with the best-in-class delivery lead time

- Robust, compact design provides long-lasting performance gains

- Unique high-volume 12-cylinder design delivers the highest displacement for the footprint

- Less maintenance than 16-cylinder engine options

- Innovative combustion technology provides efficient and stable combustion

- Spark-ignited lean-burn units ensure low emissions

- Fast cycle times and implementation — up and running in 24 weeks

- Smallest footprint in the competitive set

- Fuel blendingGuascor Energy fuel blending allows the engine to run on two different fuels or a mixture of them. This system was initially developed to work with Biogas as the primary fuel and Natural Gas as the secondary. The blending is done in the engine, not outside, saving problems and space to the end user. Guascor Energy supplies a compact and complete solution. It is possible to change modes at full power, so there is no need to stop the engine. From a real 100% Biogas – 0% Natural Gas to a 100% Natural Gas – 0% Biogas and any fuel ratio in between. With the easy start capability, the engine can be selected to run on Biogas but start with Natural Gas. It will automatically change to 100% Biogas once it reaches the rated speed, avoiding the typical starting problems associated with the use of biogas. The system is not only able to work with Biogas and Natural Gas but can also be used to blend many other gases, like Propane with Natural Gas, or hydrogen with Natural gas or even Biogas.

- Using gas to power vessels and other marineGuascor Energy has been supporting for decades marine energy transformation through reliable auxiliary power generation and electrical propulsion at constant speed. Our gas engines admit to work with natural gases with methane numbers as low as 70.

Gas Marine Auxiliary generation sets

Complete power generation sets for the auxiliary applications with a power output from 256 Kwe to 888 KweGas Marine Electric propulsion Sets

Electric propulsion sets available also from 256 Kwe to 888 KweDownloads

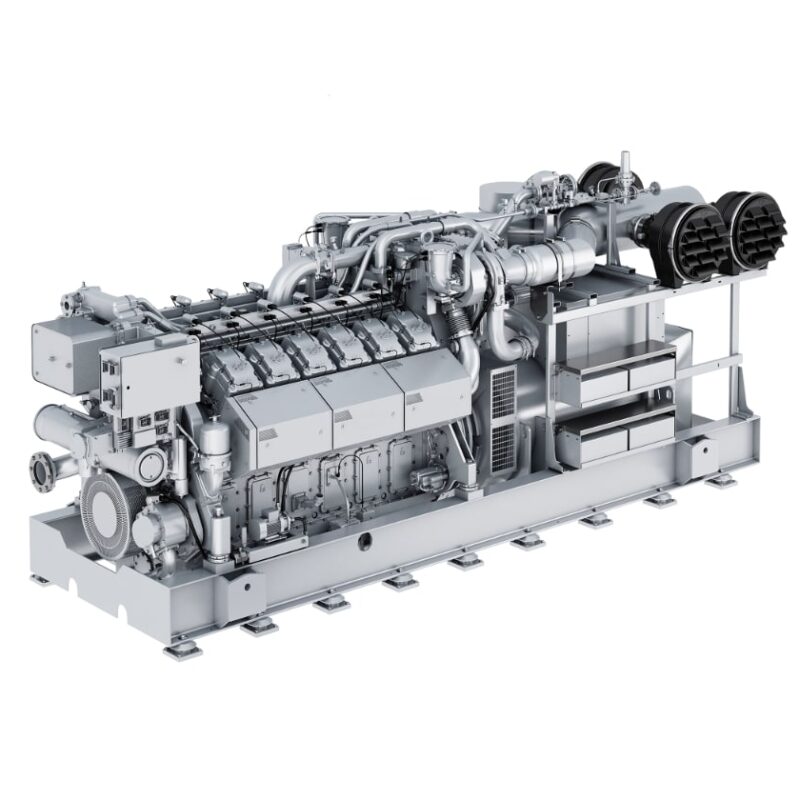

- High performance and fuel flexibility combinedA cost-efficient and compact solution for power generation and cogeneration processes, this series of Guascor Energy gas engines represents a new design concept with advanced technology incorporated into the cylinder heads, valves, camshafts, and high efficiency turbochargers.

HM Engines

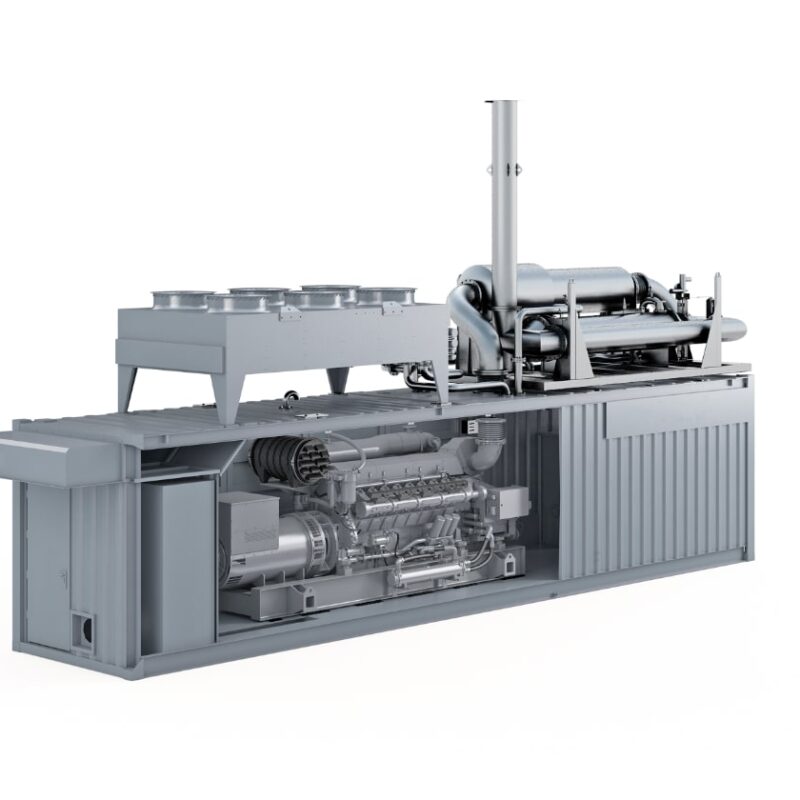

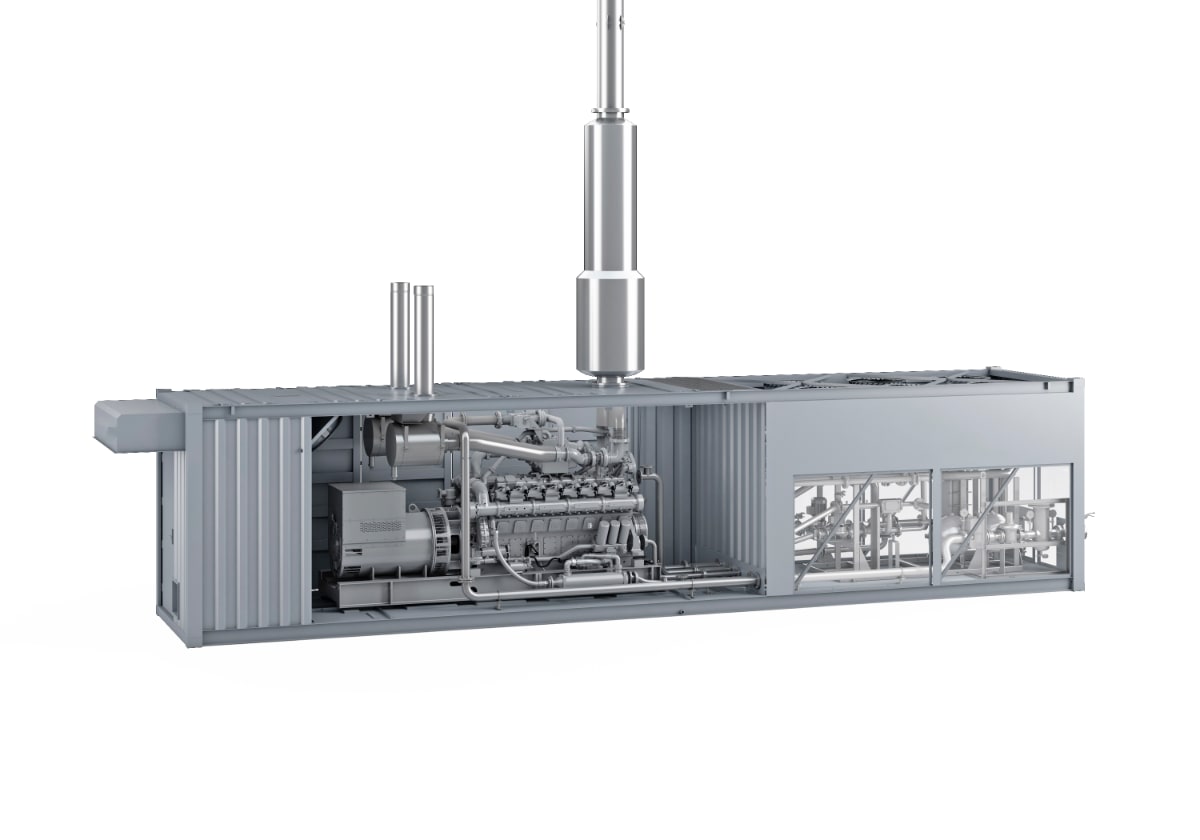

Electronically carbureted, the HM gas engine family has an output range that goes from 520 to 1373 kWb at 50 Hz and 60 Hz. The series may be fueled by natural gas, sewage and landfill gas, LPG& propane, low methane coal mine gas and hydrogen. This engine provides high performance, low life-cycle cost, fuel flexibility and exceptional fuel blending capability as required. HM series engines are based on the Miller cycle. With a dry exhaust manifold, they are turbocharged and feature single or double stage charge-air cooling. Different auxiliary water circuit temperatures are possible and oil cooler in main circuit is also available as an option. The HM Series of engines are supplied as a stand-alone engine, genset or in a fully containerized unit and also include the Guascor Energy integrated engine control, GCS-E for the best performance with controlled emissions. - A robust & reliable solution for maximum versatilityInnovative compact engine design and combustion technology for versatile use from 190 to 1,150 Kw. This Guascor Energy engine series accepts all type of combustion gases from syngas to propane and blending.

SL Engines

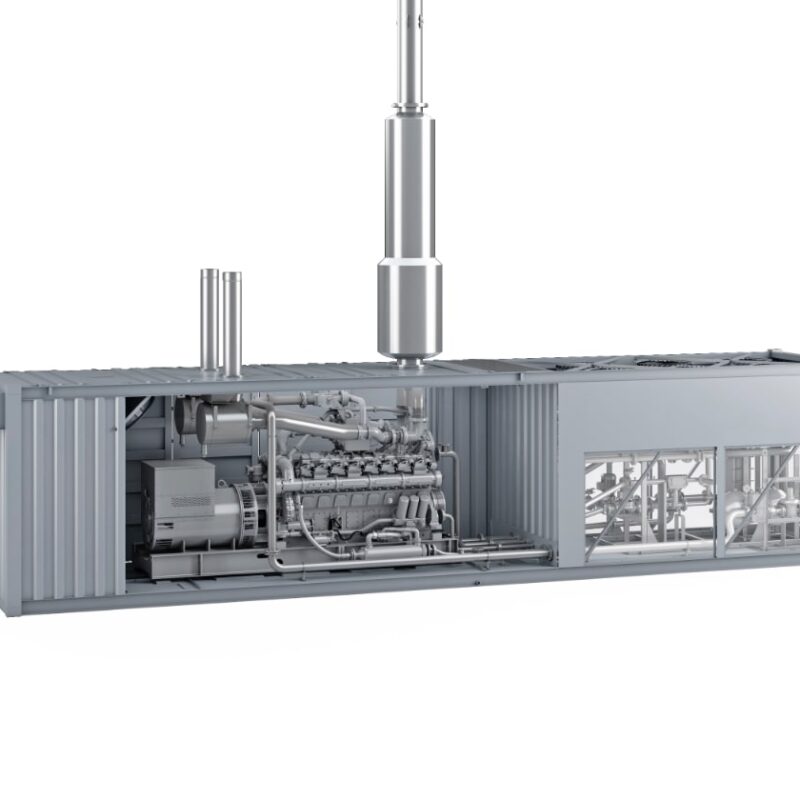

Ideal for power generation, cogeneration/trigeneration, mechanical drive and marine applications – the lean burn, electronically carbureted SL gas engines have an output range from 209 to 1150 kWb at 50 Hz and 60 Hz.Providing an excellent solution when fueled by natural gas, landfill and sewage gas, flare and well gas, LPG& propane, syngas and also hydrogen, the SL Series is a cost-efficient choice in both implementation and service. Great fuel flexibility and with fuel blending availability, this series is also an eco-friendly solution. Along with fast start availability, a high load acceptance capability is one of the main features of this engine series. Robust, reliable and with superb fuel flexibility, this Otto cycle turbocharged and charge-aircooled engine series features a single or double circuit cooling system. There is a high temperature option in the main cooling circuit, with temperatures of up to 120ºC possible. If required, the auxiliary cooling circuit can deliver a different temperature. The main cooling circuit may also feature an oil cooler. With a dry or wet exhaust manifold, single or double stage charge-air cooler and reduced oil consumption, this series of engines can include emissions control if required and is compliant with the latest U.S emissions standards, being EPA certified for natural gas power generation, for example. Supplied as a standalone engine, genset or in a fully containerised unit, integrated GCS-E and GCS-G genset control systems are available for some applications.Tri-fuel mobile solution

Three different types of fuel without any power derate due to input fuel: this is what our G-56SL engine offers in this 45 ft containerized unit, in compliance with the strictest emission levels defined by the United States Environmental Protection Agency (EPA). A reliable, flexible and high performing solution, that reduces costs and ensures high operational availabilitySM Engines

Lean burn and electronically carbureted the SM series of gas engines provide an excellent solution for power generation, cogeneration and trigeneration applications. Fueled by natural gas, landfill and sewage gas, LPG& propane, outputs range from 1055 to 1100 kWb when fueled with natural gas, landfill or sewage gas in 50 Hz and 60 Hz configurations. When fueled with propane or LPG, outputs are from 275 to 906 kWb at 50 Hz and 60 Hz, respectively. This Miller cycle series of engines are turbo-charged and include two-stage charge-air cooling if required. A double cooling circuit system allows different temperatures to be achieved in the auxiliary cooling circuit while an oil cooler in an additional option for the main cooling circuit. Among the key characteristics of this series of engines are standard interchangeable parts and very high operational availability – key competitive advantages. With a dry or wet exhaust manifold configuration, an emissions control option means this series is compliant with the latest U.S. emissions standards and it has reduced oil consumption too. This engine series may be supplied as a stand-alone engine, as a genset or as a fully containerised unit.SR Engines

Robust and reliable, the rich burn, electronically carbureted SR Series gas engines offer great performance for power generation and cogeneration applications. Outputs range from 180 to 870 kWb at 60 Hz and this series may be fueled natural gas and well gas with superb fuel flexibility. This ecofriendly engine series meets the latest U.S. emissions standards and has great flexibility for load acceptance too. Turbocharged and with single or double stage charge-air cooling, the SR Series features a double circuit cooling system in which different auxiliary cooling circuit temperatures are achievable. With a wet exhaust manifold, the SR Series machines are supplied as a stand-alone engine, as a genset or as a fully containerised unit.